I once watched a shipment of fresh produce arrive bruised and half-wrecked. The road wasn’t the problem, the suspension was. The company had chosen the wrong system for the job, too rigid for delicate goods, too stiff for uneven roads.

That was a turning point for me.

I realized that suspension isn’t just about ride comfort, it protects your cargo and your reputation.

If you’ve ever asked yourself, “What’s the best suspension for my trailer?” then this article is for you.

This guide covers 7 different types of semi trailer suspension. I’ll explain what each one does, where it performs best, and how to know if it’s the right fit for your work. You’ll walk away with a clear tool to help you compare and choose with confidence.

Let’s start!

Quick Comparison

Before we dive deep into each suspension type, here’s a quick side-by-side look.

If you’re short on time or just need a snapshot, this table gives you a fast way to spot the differences:

| Suspension Type | Ride Quality | Load Capacity | Terrain Suitability | Price Range | Best For |

| Leaf Spring | Firm, bumpy | Medium to high | Highways, rough roads | $$500 –$$1,000 | Budget buyers, general hauling, rugged routes |

| Torsion Axle | Smooth, quiet | Low to medium | Paved roads, light loads | $$800 –$$1,500 | Light-duty, small trailers, urban delivery |

| Air Ride | Very smooth | Medium to high | Highways, paved roads | $$1,500 –$$2,000 | Fragile goods, long hauls, comfort-first jobs |

| Rubber | Soft, minimal noise | Light to medium | Paved, mild off-road | $$750 –$$1,500 | Livestock, utility trailers, urban routes |

| Single Point | Firm, stable | Very high | Extreme off-road, mining | $$5,000 –$$10,000 | Mining, logging, construction |

| Bogie | Stable, firm | Very high | Highways, moderate rough | $$2,500 –$$3,000 | Long-haul, agriculture, heavy freight |

| Mechanical | Very firm | Very high | Highway, rough roads | $$2,500 –$$3,000 | Heavy-duty work, mining, construction |

You’ve seen how they compare. Now, let’s take a deeper look into what each suspension really delivers on the road.

1. Leaf Spring Suspension

I used to think suspension didn’t matter much. If the trailer could hold the weight, I figured it was good enough.

But then I hit a series of uneven roads with a load of steel beams. Every bump rattled through the trailer. By the time I arrived, two straps had loosened. One beam had shifted.

That trip taught me something the hard way: choosing the wrong suspension can cost you time, cargo, and confidence.

If you’re moving heavy loads, especially over mixed terrain, you’ll likely come across leaf spring suspension. Let’s break it down so you can decide if it fits your work.

What This Suspension Is

Leaf spring suspension is one of the oldest and most widely used systems in trailers. It’s made of stacked metal strips called leaves that flex to absorb shock. The springs are curved and mounted between the axle and the trailer frame.

When you hit a bump, the leaves bend. That bending spreads the weight across the trailer and helps reduce the jolt.

Why do so many companies still choose it today?

Because it works. It’s simple, strong, and proven. You’ll see it on flatbeds, dump trailers, and equipment haulers especially where heavy loads are involved and the roads aren’t always kind.

Price Range: A standard leaf spring suspension usually costs between $50 and $200 per spring, depending on size and brand. You’ll need to factor in how many axles your trailer has and how much weight you’re hauling.

Now that you understand the basics, let’s look at the features that matter most in day-to-day use.

Key Features

Choosing a suspension system is about more than just price. How does it ride? How long will it last? Here’s what to consider:

- Ride Quality: The ride is firm. That can be good for weight support, but rough when the trailer is empty or lightly loaded. Not the best choice if you’re hauling delicate goods.

- Weight Capacity: These are built for heavy loads. The more leaves you have, the more weight you can carry up to 7,500 pounds per axle or more.

- Installation and Compatibility: Leaf springs are everywhere. That means parts are easy to find, and installation is straightforward for most standard trailers.

- Durability: With fewer moving parts than air systems, leaf springs hold up well. They handle tough jobs and rough roads but should still be checked for rust or cracks.

- Terrain Adaptability: They perform fine on highways and gravel roads. On very rough or uneven terrain, the ride can feel harsh.

- Adjustability or Tech Features: Leaf springs are mechanical. No air valves, no sensors. What you see is what you get.

- Braking and Handling: When the suspension is in good shape, it helps keep the trailer balanced. But since it’s less flexible, it doesn’t absorb sudden shifts as smoothly as more advanced systems.

So what’s the bottom line? Leaf springs are reliable and strong, but they don’t give the softest ride.

Pros and Cons

Like every system, leaf springs come with trade-offs. Let’s be honest about what works and what might not.

Pros:

- Simple and affordable

- Durable under heavy weight

- Easy to find and replace

- Good for consistent use on mixed roads

Cons:

- Can feel rough when lightly loaded

- Heavier than other suspension types

- No adjustability or advanced features

Still with me? Good.

You might be wondering: “Who is this suspension really for?” Let’s talk about that next.

Ideal Users

From what I’ve seen in the field, leaf spring suspension is a good fit if your focus is on hauling heavy loads without breaking the bank. Here’s who benefits most:

- Construction companies moving cement, steel, or machines

- Manufacturers running trailers with consistent, heavy cargo

- Agriculture businesses that don’t need a soft ride for produce

- Individual buyers who want something reliable and budget-friendly

If you’re hauling furniture, electronics, or anything fragile, you might want to look elsewhere. But if you’re pulling weight and working on a budget, leaf spring gets the job done.

And if you’re building or upgrading a trailer, the right suspension is only one part of the puzzle. At Rhinotrail, we help buyers like you choose the full setup from container trailers to low-beds, built to handle real work.

2. Torsion Axle Suspension

The first time I hauled a lightweight generator on a trailer with torsion axles, I noticed something right away.

It was quiet.

There was no clanking, no bouncing. Just a steady, smooth ride, even over the cracked back roads behind the industrial park. I didn’t think suspension could make that big of a difference, but it did.

If you’ve ever hauled sensitive cargo, or just want something that rides smoother without needing much attention, torsion axle suspension might be worth a closer look.

Let’s start by understanding what it is and why it’s different.

What This Suspension Is

A torsion axle suspension works differently than leaf springs. Instead of using stacked metal leaves, it uses a solid axle tube with rubber cords inside. These cords twist and compress as the wheels move, absorbing shock along the way.

There are no metal-on-metal parts flexing back and forth. That means less noise, fewer vibrations, and a ride that feels more controlled especially when you’re lightly loaded or empty.

Why do some buyers prefer it?

- It rides smoother than leaf springs

- It requires less maintenance

- It works well for trailers that carry lighter or more fragile items

You’ll often see torsion axles on enclosed cargo trailers, boat trailers, RVs, or any setup where comfort and cargo protection are priorities.

Price Range: A typical torsion axle setup costs between $500 and $1,500 per axle, depending on the weight rating and manufacturer. You’ll want to check your trailer’s specs before choosing one.

Now that you know how it works, let’s explore what it actually offers on the road.

Key Features

Understanding the performance side of this suspension can help you figure out if it fits your route and load type. Here’s what to look at:

- Ride Quality: Torsion axles give a smooth, quiet ride. The rubber cords soak up shock well, making this a solid option for fragile or lightweight cargo.

- Weight Capacity: They’re available in a wide range, usually between 1,000 and 7,000 pounds per axle. Just be sure to match the axle rating with your total trailer weight.

- Installation and Compatibility: These axles bolt directly to the trailer frame. That makes installation clean. But if something breaks inside, it can’t be repaired—you’d need to replace the whole axle.

- Durability: Because there are fewer moving parts, there’s less wear over time. No springs to rust or bushings to replace.

- Terrain Adaptability: Torsion axles perform best on paved roads or light gravel. On extremely rough or off-road terrain, they may not absorb uneven forces as evenly as other types.

- Adjustability or Tech Features: These are fixed systems. Once installed, the ride height and stiffness are set. There’s no air adjustment or built-in leveling.

- Braking and Control Impact: Each wheel moves independently. That helps with cornering and road grip, especially on uneven surfaces.

Pros and Cons

Like any part of your trailer, this system has its strengths and trade-offs. Here’s a quick look:

Pros:

- Smooth ride with less noise

- Low maintenance needs

- Fewer parts to wear out

- Better control on paved roads

Cons:

- Higher upfront cost

- No adjustability after installation

- Harder to repair, usually replaced as a whole unit

Ideal Users

From what I’ve seen, this suspension makes the most sense for jobs that don’t involve rough terrain or massive loads. It’s a great option if your top priority is a clean, steady ride.

You’ll want to consider it if you:

- Haul fragile goods like electronics or appliances

- Run urban deliveries over paved roads

- Operate boat trailers in areas with moisture or salt exposure

- Pull recreational or enclosed trailers where comfort and quiet matter

- Move light- to mid-weight cargo that doesn’t shift much during transit

But if you’re hauling rocks, construction gear, or running routes deep into job sites? You might need something tougher.

3. Air Ride Suspension

If you’re asking yourself whether the suspension under your trailer really matters, trust me, it does. Especially if you’re hauling delicate or high-value goods.

That’s where air ride suspension steps in.

What This Suspension Is

An air ride suspension uses airbags instead of metal springs. These airbags are filled with compressed air and mounted between the trailer axle and the frame. As your trailer hits bumps or uneven surfaces, the airbags compress and absorb the shock. Then they bounce back, keeping the trailer steady.

This system responds better to road conditions than mechanical suspensions. It helps maintain a consistent ride height, even when the trailer is loaded unevenly.

Why do so many companies go with air ride?

- It protects sensitive cargo

- It reduces vibration and noise

- It makes long hauls more comfortable

You’ll often find air ride systems on refrigerated trailers, dry vans carrying electronics, or any trailer used for fragile freight.

Price Range: Expect to pay between $1,500 and $2,000 extra per trailer for air ride suspension, depending on specs and brand.

So how does it actually perform on the road? Let’s take a look at the key features.

Key Features

If you’re trying to compare options, you’ll want to look at what air ride suspension offers in real-world use:

- Ride Quality: Very smooth. The airbags soak up road shock and reduce trailer bounce. This is one of the best systems for fragile or sensitive cargo.

- Weight Capacity: Can handle light to heavy loads. Most air ride systems are built to match standard axle ratings, but always check your trailer specs.

- Installation and Compatibility: More complex than leaf or torsion setups. It requires airlines, valves, a compressor, and control systems. Retrofitting can be tricky.

- Durability: Air ride systems last with proper care, but parts like compressors or airbags may need replacement after heavy use or exposure to moisture and debris.

- Terrain Adaptability: Performs best on paved roads or highways. It works on light off-road conditions but isn’t ideal for extreme rough terrain.

- Adjustability or Technology: One of the best features. You can often adjust ride height or stiffness. Some systems auto-level depending on load weight.

- Braking and Control Impact: Improves overall control. Because the suspension keeps the trailer level, braking stays consistent even on uneven surfaces or in curves.

Before we move on, ask yourself: do you often carry cargo that needs protection from vibration? Are your drivers covering long distances daily? If yes, these features may be what you’re looking for.

Pros and Cons

Like every system, air ride has upsides and limitations. Here’s a quick breakdown to help you see both sides:

Pros:

- Smooth ride that protects cargo

- Reduces wear on tires and trailer body

- Adjustable for different weights and roads

- Better control during stops and turns

Cons:

- Higher upfront cost than other systems

- Requires more parts and installation time

- Components like airbags and valves need upkeep

If you’re weighing cost versus comfort, these trade-offs matter. So who’s most likely to benefit from an air ride setup?

Ideal Users

In my experience, air ride suspension fits best with operations where cargo quality, ride comfort, or long distances are top concerns. You might want to consider it if you:

- Transport electronics, furniture, or fragile goods

- Run refrigerated trailers that need steady temperature and minimal vibration

- Operate in long-haul logistics where driver fatigue is a real concern

- Work in urban delivery with frequent stops and uneven pavement

- Need a smooth ride for high-value cargo that can’t shift or bounce

But if your work involves off-road routes, constant exposure to dirt, or heavy construction hauling? Another suspension type might be better suited.

4. Rubber Suspension

A few years back, I was moving a batch of packaged ceramics. Tight delivery window, long stretch of country road. By the time I arrived, several pieces had cracked. Not from poor packing. It was the vibration. The constant bouncing wore down the load mile by mile.

That job made me pay more attention to suspension. I started asking “What else is out there besides leaf or air?” That’s when I found rubber suspension. And for certain trailers, it can be a smart choice.

Let’s take a closer look.

What This Suspension Is

A rubber suspension system uses rubber cords or inserts usually inside a solid axle to absorb road shock. As the trailer moves, the rubber compresses and flexes, softening the impact of bumps and vibrations.

There’s no steel spring or airbag here. Just a clean, sealed system relying on the natural give of rubber.

Why do some drivers and companies go with it?

- It’s quiet

- It requires very little maintenance

- And it protects light or delicate loads from bounce and rattle

You’ll often see rubber suspension on utility trailers, boat trailers, or smaller specialty setups like livestock carriers.

Price Range: A rubber suspension axle typically costs between $750 and $1,500, depending on capacity and brand. It’s often sold as a full axle unit.

Now that you’ve got the basic idea, let’s go deeper into how this system actually performs.

Key Features

Not every job needs advanced air systems or heavy-duty springs. Sometimes, simple works best. Here’s what you can expect from rubber suspension:

- Ride Quality: It’s smoother than leaf springs, but not as soft as air. Great for protecting cargo on paved or moderately rough roads.

- Weight Capacity: Most rubber suspension axles support light to mid-range loads. They’re not meant for heavy construction hauls.

- Installation and Compatibility: Many systems are sold as ready-to-mount axles, which makes setup easier. But retrofitting an existing trailer might take extra work.

- Durability: The rubber parts are sealed inside and protected from dirt and weather. That means fewer parts to check or replace.

- Terrain Adaptability: Performs best on highways and well-kept roads. Not ideal for rugged off-road use or uneven worksites.

- Adjustability or Tech Features: Rubber systems are fixed. No onboard height control or stiffness settings.

- Braking and Control Impact: Offers good stability under normal conditions. Each wheel reacts independently, which helps during turns and stops.

So far so good, but every system has its trade-offs. Let’s go over the pros and cons.

Pros and Cons

When you’re trying to decide what fits your work best, it helps to see both sides clearly.

Pros:

- Very low maintenance

- Quiet and smooth ride

- Resistant to rust, dirt, and moisture

- No grease points or metal-on-metal contact

Cons:

- Lower weight limits than leaf or air

- No way to adjust ride settings

- Not built for extreme terrain or heavy loads

Now that you’ve seen the breakdown, ask yourself this: do you usually haul light cargo on paved roads? Are you tired of noisy, high-maintenance suspension?

If so, rubber might be worth looking into.

Ideal Users

Rubber suspension works best when you want simplicity and a smooth ride—but don’t need heavy-duty hauling.

You might be the right fit if you:

- Haul livestock or animals that need a quiet ride

- Operate utility trailers for farm or warehouse work

- Transport fragile items like glass or finished products

- Work in urban delivery with light loads and tight routes

I’ve seen smaller logistics firms and rural haulers use rubber suspension with great results. It’s not for every job, but in the right setting, it’s reliable and low stress.

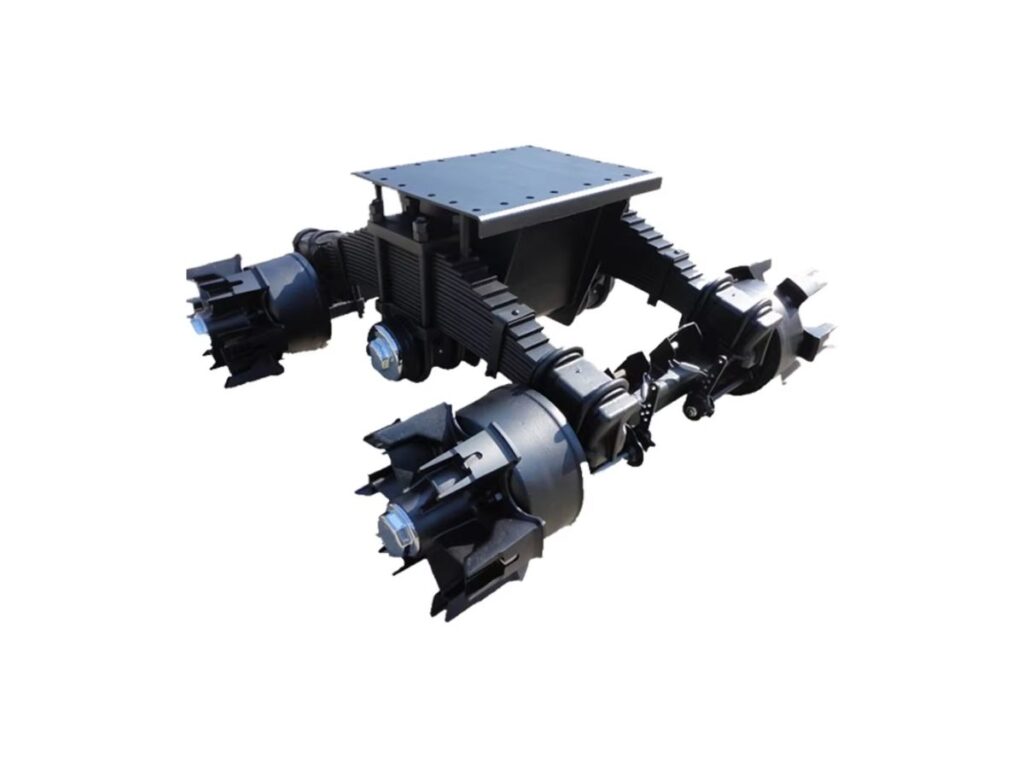

5. Single Point Suspension

A while back, I worked with a client who had constant issues hauling gravel up steep, uneven mining paths. Every trip ended with misaligned axles and loose connections. They were using a basic multi-link setup—meant for highways, not heavy terrain.

That’s when we switched them to single point suspension. The change was immediate. The load stayed stable, even through deep ruts and slopes. That trailer didn’t just survive the trip. It handled it.

If you’re wondering what kind of suspension can hold up under tough conditions and carry serious weight, this is one worth knowing.

What This Suspension Is

A single point suspension uses one central pivot called a trunnion that connects all axles to the trailer frame. Instead of using multiple points of attachment, everything is mounted from a single anchor. That’s where the name comes from.

This pivot lets the axles move together, almost like a teeter-totter. When one side goes up, the other adjusts automatically. That movement keeps the load balanced, especially on rough or uneven roads.

Why do companies go with this option?

- It’s tough

- It’s reliable in extreme conditions

- And it spreads weight evenly across multiple axles

You’ll find this suspension type on trailers working in mining, logging, and off-road construction, anywhere that road conditions are unpredictable and the loads are heavy.

Price Range: A single point suspension system usually costs between $5,000 and $10,000, depending on the specs and brand. It’s a big investment, but it’s built for heavy-duty work.

Key Features

If your hauls involve steep hills, rocky trails, or oversized equipment, here’s what to expect from a single point suspension:

- Ride Quality: It’s solid and stable. Not the softest ride, but it handles bumps and dips without throwing the load around.

- Weight Capacity: Built for large hauls. Some setups handle up to 50,000 pounds or more, depending on axle count and design.

- Installation and Compatibility: Usually found on purpose-built trailers. Retrofitting takes more time and might not be possible with lighter-duty frames.

- Durability: This suspension is designed for impact and load stress. Fewer moving parts means less to break, even under pressure.

- Terrain Adaptability: Ideal for off-road or mixed terrain. The pivot lets the wheels move with the ground instead of fighting it.

- Adjustability or Tech Features: Basic by design. No sensors or electronic features, just mechanical strength and simplicity.

- Braking and Control Impact: Because axles stay aligned and balanced, braking is steady. It also helps prevent sway when navigating uneven roads or heavy inclines.

So, how does it stack up overall? Let’s look at the trade-offs.

Pros and Cons

Like every suspension setup, this one has benefits and limitations. Here’s a quick breakdown:

Pros:

- Built for extreme conditions

- Strong weight distribution

- Minimal maintenance needs

- Great for long-term heavy hauling

Cons:

- Rougher ride on smooth roads

- Expensive upfront

- Less suitable for light or flexible-use trailers

If your trailers stay on highways or carry variable cargo, this might not be the best fit. But if you deal with consistent, heavy, off-road work, it could save you time, money, and headaches down the line.

Ideal Users

This suspension isn’t for everyone. But for certain industries and jobs, it hits the mark.

You might consider single point suspension if you:

- Haul heavy mining equipment on dirt and gravel

- Operate off-road construction trailers

- Run logging operations where road conditions change daily

- Need a trailer that can take a beating and keep working

It’s especially useful when your loads are big and your paths aren’t paved.

At Rhinotrail, we work with companies in mining, construction, and logistics who face these same conditions every day. Whether you’re hauling equipment or raw materials, our trailers are built with the suspension systems that hold up under pressure.

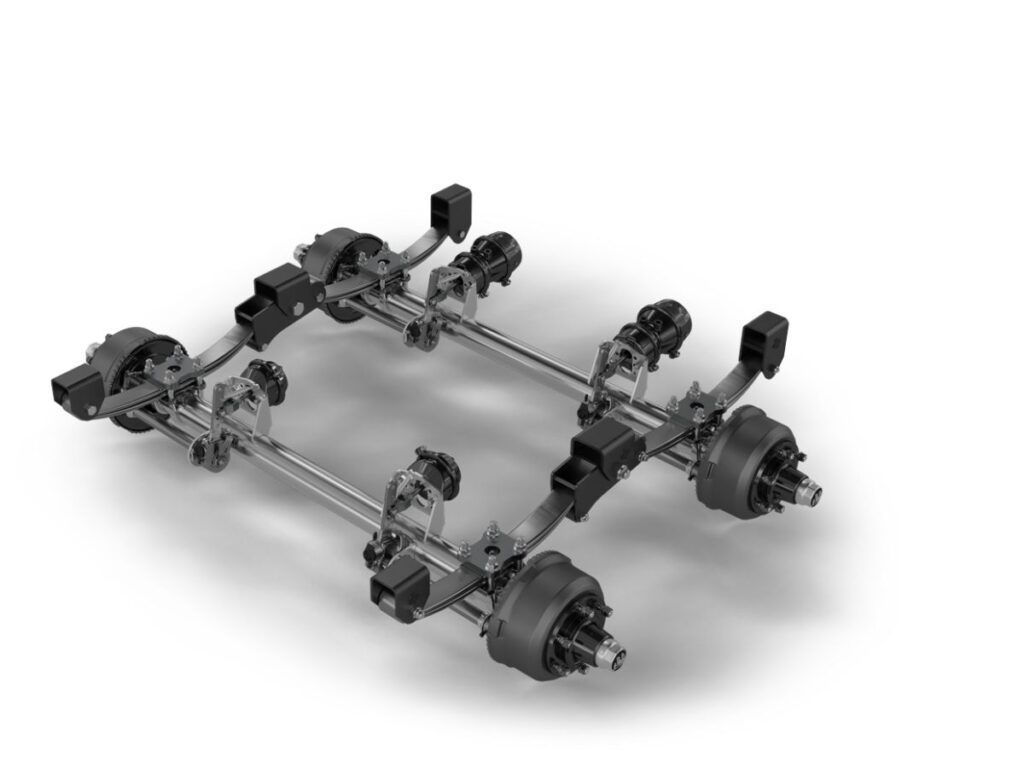

6. Bogie Suspension

I once worked with a small fleet owner who ran long hauls carrying bulk materials across rough stretches of highway. His trailers used to take a beating, misaligned axles, tire wear, stress fractures. But after switching to bogie suspension, he told me: “The ride’s not soft, but the trailer holds together.”

That stuck with me. Because for some jobs, stability matters more than comfort.

If you’re hauling heavy loads and need strength over softness, bogie suspension might be worth considering.

What This Suspension Is

A bogie suspension uses a set of two or more axles grouped together into a single frame, called a bogie. These axles work as a unit, mounted under a central point on the trailer. As the load shifts or the trailer hits bumps, the bogie rocks slightly, distributing the force evenly across the axles and wheels.

This setup is great for spreading weight and handling pressure. It keeps the trailer grounded and helps extend the life of both the suspension and the tires.

Why do some operators stick with bogie suspension?

- It’s strong

- It balances loads well

- It’s ideal for consistent, heavy hauling

You’ll often see it on flatbeds, dump trailers, or bulk carriers running long distances.

Price Range: A bogie suspension setup usually costs between $2,500 and $3,000, depending on load capacity and brand. It’s not the cheapest, but it’s built to last.

Key Features

Bogie suspension is more than just tough. Here’s what you can expect from it:

- Ride Quality: It leans firm. Not as soft as air ride, but it helps keep the trailer steady and predictable.

- Weight Capacity: Designed for heavy-duty loads. Many bogies handle 24 to 32 tons comfortably.

- Installation and Compatibility: Often comes as a pre-built module. Easy to bolt onto the trailer frame, though not always ideal for retrofits.

- Durability: Built for rough use. Minimal moving parts and strong components make it dependable over the long haul.

- Terrain Adaptability: Performs best on paved or moderately rough roads. Not ideal for deep off-road routes or uneven surfaces like a single point suspension would handle.

- Adjustability or Technology: Most setups are mechanical with no ride adjustment. Some advanced models use air springs to soften the ride.

- Braking and Control Impact: With even axle load distribution, braking stays stable. You get less sway and better control under pressure.

Pros and Cons

Like any suspension choice, bogie systems have benefits and trade-offs. Here’s a straight look:

Pros:

- Distributes weight well

- Strong and built for pressure

- Easy to service or replace

- Works reliably over long distances

Cons:

- Rides firm, especially with light loads

- Not great for extremely rough or off-road conditions

- Lacks fine-tuned ride control or adjustability

Before choosing, ask yourself: do you prioritize strength and stability? Do your trailers mostly stick to highways with heavy cargo?

If yes, this might be the setup that saves you stress and maintenance costs.

Ideal Users

Bogie suspension is a solid fit for haulers who value reliability under pressure. You might want to consider it if you:

- Run flatbed or bulk trailers across long highway routes

- Operate in agriculture or construction, hauling soil, grain, or raw materials

- Move consistent, heavy cargo that stays the same trip after trip

- Need something simple, strong, and ready to work hard

If your loads vary or your routes involve delicate cargo or fragile goods, other suspension systems might be a better match.

7. Mechanical Suspension

I once helped a customer who was running trailers through rural roads in the rainy season. Nothing fancy, just heavy hauls, long days, and a rough route. His trailers didn’t need to be high-tech. They needed to work. And they needed to last.

That’s when he switched to mechanical suspension. No air systems. No sensors. Just springs, strength, and simplicity. Since then, he hasn’t looked back.

If you’re hauling steady loads over long distances or rough surfaces, this might be a setup worth exploring.

What This Suspension Is

A mechanical suspension is built around leaf springs, layers of curved steel stacked together. These springs flex under pressure to absorb bumps and keep the trailer balanced. You’ll also find components like equalizers and shackles that help distribute weight across the axles evenly.

It’s simple. And that’s part of the appeal.

Why do many companies choose this type?

- It’s affordable

- It handles heavy loads

- And it’s easier to maintain

You’ll find mechanical suspension used widely in mining, construction, and agriculture. Industries where reliability matters more than comfort.

Price Range: A mechanical suspension system typically costs between $2,500 and $3,000, depending on axle count, brand, and capacity.

So, what exactly does this system offer on the road? Let’s get into that next.

Key Features

Once you understand the core structure, the features become more meaningful. Here’s what you can expect from mechanical suspension in day-to-day use:

- Ride Quality: It’s a firmer ride compared to air or rubber systems. Not the best for fragile goods, but it handles bumps without breaking down.

- Weight Capacity: Great for heavy hauls. Many setups can handle serious payloads, making this ideal for tough loads.

- Installation and Compatibility: Easy to install and commonly used. You’ll find it in many standard trailer builds. Good for fleets that need something consistent.

- Durability: Strong, reliable, and built to last. Fewer moving parts means fewer points of failure.

- Terrain Adaptability: Works well on highways and moderately rough roads. Not ideal for deep off-road trails or steep climbs, but good for mixed use.

- Adjustability or Technology: This system is all mechanical. No smart sensors or auto-adjusting features. But that also means there’s less to go wrong.

- Braking and Control Impact: The even axle load helps with braking. It keeps the trailer steady, especially when you’re fully loaded and moving downhill or through tight turns.

All things considered, this suspension works best where predictability and strength matter most.

Let’s look at the pros and cons to help you weigh it out.

Pros and Cons

When deciding on a suspension type, it helps to see the whole picture. Here’s how mechanical suspension stacks up:

Pros:

- Simple and strong

- Low upfront cost

- Less maintenance required

- Handles heavy loads without fuss

Cons:

- Rougher ride, especially on light loads

- Not ideal for fragile or high-value cargo

- No ride height or stiffness adjustments

Is it perfect for every job? No. But in the right setting, it gets the job done, day after day.

Ideal Users

This setup isn’t trying to be fancy. It’s for people who need function, not flash. Mechanical suspension is a great fit if you:

- Move heavy mining or construction loads on paved or semi-rough roads

- Work in agriculture, transporting machinery or produce

- Run logistics routes that stay mostly on highways

- Want a system that just works, without needing extra attention

If your work involves long hauls, consistent cargo, and reliable performance, this suspension might be all you need.

Conclusion

We’ve looked at 7 different suspension types, each with a job, a limit, and a purpose.

You’ve seen the comparisons, now it’s time to decide what fits your trailer, your cargo, and your future.

I’ve made wrong choices before, and they cost me, but I’ve also made the right ones and those changed everything.

Don’t just read this, act on it. That’s how real progress happens.

Need a trailer that’s built for your roads and your loads? Let Rhinotrail help. Contact us today.

Which suspension felt right for your work?

Explore Related Resources

If you’re looking for more insights, we’ve put together a list of helpful articles that you might enjoy:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.