You can have the best driver and the best engine. But if your dump body doesn’t match the load, none of that matters.

I’ve seen it play out too many times, dirt spilling from a side dump where a straight end would’ve been safer. Or demolition debris bending thin aluminum walls meant for sand.

I’ve learned the hard way what happens when form doesn’t match function.

That’s why I put this list together.

Inside this article, you’ll get a fast, clear look at 9 dump truck body types, what they are, how they work, and which jobs they’re made for. You’ll leave with the knowledge to make a confident, job-ready decision.

So, let’s start!

Quick Comparison

Before we dive into each dump body in detail, here’s a quick side-by-side look. This table gives you a side-by-side breakdown of all 9 dump truck body types, so you can quickly compare function, cost, and more before reading the full reviews.

| Body Type | Dump Direction | Load Volume (cu yd) | Common Material | Best For | Limitations | Est. Price Range |

| Standard Dump Body | Rear | 10–16 | Steel, Aluminum | General construction, sand, soil | Limited capacity, tipping risk | $$70,000$$110,000 |

| Transfer Dump Body | Rear | 20–30 | Steel | Road work, asphalt, gravel | Complex operation, extra maintenance | $$80,000$$250,000 |

| Side Dump Body | Side | 20–30 | Steel, Aluminum | Spreading, road base, trench fill | Needs side clearance, wind risk | $$40,000$$80,000 |

| Bottom (Belly) Dump Body | Bottom | 20–26 | Steel | Highway paving, gravel windrows | Flat terrain only, limited materials | $$50,000$$100,000 |

| Articulated Dump Body | Rear | 22–45 | Steel | Mining, steep or uneven sites | Too large for urban areas | $$300,000$$600,000 |

| Off-Highway Dump Body | Rear | 40–100+ | Thick Steel | Large-scale mining & quarries | Off-road use only, high cost | $$500,000$$1M+ |

| Semi-Trailer End Dump | Rear | 20–30 | Steel, Aluminum | Long-haul bulk transport | Tip risk, needs flat unloading area | $$30,000$$70,000 |

| Haul Dump Body | Rear | 40–100+ | Heavy Steel | Quarry, mine-site haulage | Not road legal, very high fuel use | $$500,000$$1M+ |

| U-Shaped Dump Body | Rear | 20–40 | Steel, Aluminum | Sticky or wet materials | Less ideal for bulky items | $$30,000$$70,000 |

Now that you’ve seen how they compare, let’s break each body down in more detail, starting with the standard dump body.

1. Standard Dump Body

I’ll be honest with you, when I first got into this business, I thought all dump trucks worked the same. If it dumped, it worked. That was the mindset.

But I quickly learned that the type of dump body changes everything.

If you’re hauling loose materials like gravel, sand, or asphalt, chances are you’ve run into—or already used—a standard dump body.

So, what exactly is it?

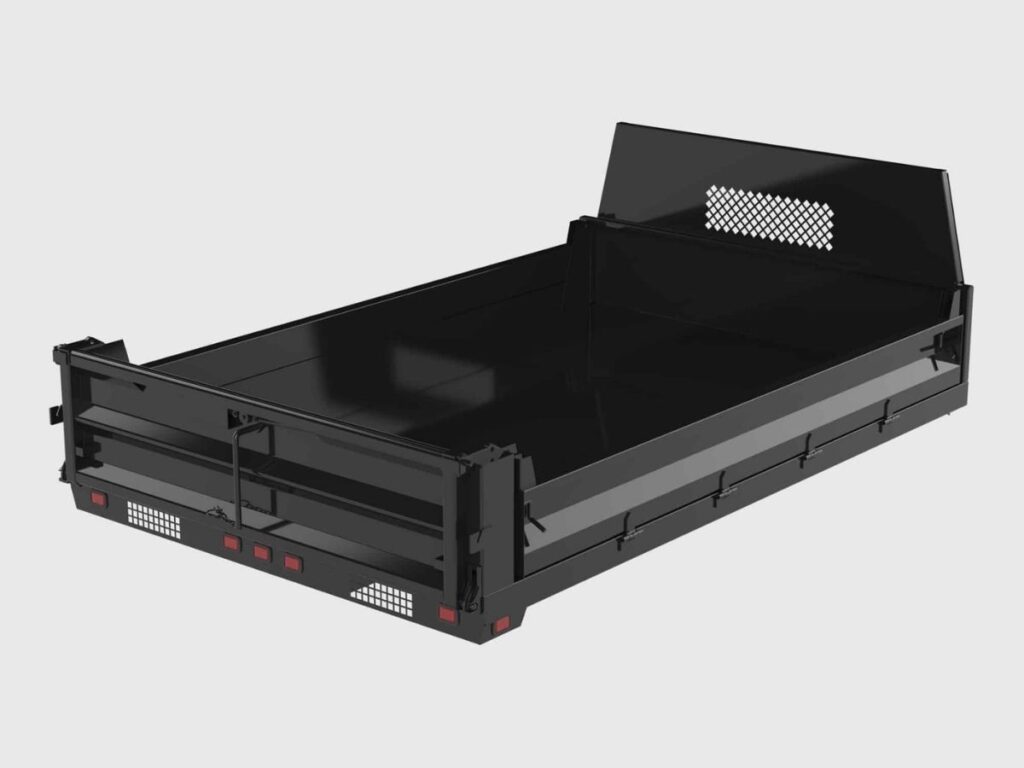

A standard dump body is a steel or aluminum bed mounted directly onto the truck’s chassis. It uses a hydraulic hoist to lift the front of the bed. This tilts the body backward, allowing the load to slide out through the tailgate.

Think of it as the most common setup for general construction and hauling jobs. Simple, reliable, and easy to operate.

Advantages

This style has stuck around for a reason. It handles a wide range of jobs without being too specialized.

Here’s what makes it a solid choice:

- Good for tight job sites, especially urban areas

- Can haul gravel, sand, soil, demolition debris, and more

- Usually costs less than specialized bodies

Specifications

If you’re comparing specs, start here:

- Load capacity: usually 10 to 20 cubic yards

- Dump angle: steep enough for most materials to slide out

- Axle setups: common ones include a single front axle with one or two rear axles

That said, not everything about it is perfect.

Limitations

Think about your site conditions and material type before choosing this option.

Standard dump bodies can struggle with:

- Sticky materials that don’t unload easily

- Rough or uneven terrain, especially off-road

- Jobs needing extreme capacity or special handling

Have you ever worked a site where your truck couldn’t dump fully?

That’s the kind of situation this body might not solve.

Cost Factors

Money matters, especially when you’re trying to outfit your fleet or stay on budget for a project.

Here’s a quick price overview:

- New medium-duty models: about $90,000 to $140,000

- New heavy-duty models: around $150,000 to $280,000

- Used trucks: anywhere from $30,000 to $230,000, depending on age and condition

But price is only part of it.

There are other costs to plan for too:

- Fuel use: averages 3 to 6 miles per gallon

- Insurance: often between $8,000 and $25,000 per year

- Tires: a full set for a large truck can cost up to $12,000

Final Thoughts

So, is this the right dump body for you?

If you need something versatile, budget-friendly, and easy to maneuver, the standard dump body might fit.

But if you’re working on steep slopes, hauling sticky material, or need maximum volume? You might want to keep reading and explore other options.

2. Transfer Dump Body

The first time I worked with a transfer dump body, I was impressed by how much material it could haul without losing flexibility on the road. We were doing a road paving job, and time was tight. The transfer setup helped us cut our trips in hal and we didn’t need extra trucks to do it.

But before you decide if this body type is right for you, it helps to understand how it works.

A transfer dump truck includes a standard dump truck that pulls a separate trailer. That trailer carries an extra load container, often called a “pup.” The cool part? The pup is transferred into the main bed using a rail system and hydraulics.

Once the container locks into the truck bed, it dumps like a standard rear loader. Most of these containers are made from steel to handle abrasive loads like gravel and asphalt. Some setups use aluminum to reduce weight, which lets you haul more legally.

Advantages

Why do operators choose transfer dumps over standard ones? Because they let you move more without needing another truck. That’s a big deal for tight deadlines or long hauls.

Here’s what makes them stand out:

- You get more payload per trip: typically 20 to 30 cubic yards total

- They fit tight spaces better than full-length tractor-trailers

- You can haul anything from sand and gravel to asphalt and base rock

- Fewer trips mean lower fuel use and labor time

But like any truck body, it’s not perfect. Let’s look at the details that matter most.

Specifications

When comparing models, these are the specs you’ll want to ask about:

- Combined load capacity: around 20 to 30 cubic yards depending on axle limits

- Dump angle: about 45 to 50 degrees for full unloading

- Material build: steel for durability, aluminum for lighter loads

- Trailer design: some transfer trailers are roll-off style, others use sliding rail systems

- Axles: usually set up with three to four axles for weight distribution

Limitations

Still, this isn’t the right fit for everyone. It has some drawbacks worth thinking about:

- More complex to operate: transferring the pup takes skill and training

- Maintenance: more moving parts, more things that can wear out

- Terrain: not great for rough or off-road conditions because of the trailer

- Regulations: trailer transfers have stricter legal limits in some regions

Cost Factors

Let’s talk money. Transfer dump trucks are a bigger investment than your basic setup. But the long-term savings from fewer trips can be worth it.

Here’s what you’re looking at:

- New models: $200,000 to $350,000 depending on brand, axle count, and power

- Used models: $80,000 to $250,000 depending on age, mileage, and condition

- Fuel use: slightly higher due to the trailer’s weight

- Insurance: more coverage needed, so premiums can range from $10,000 to $25,000 per year

- Maintenance: budget extra for the trailer’s wheels, rail system, and hydraulic components

Final Thoughts

In my experience, transfer dump trucks are a great choice if you’re working on large-scale projects that need high volume and efficiency. They’re reliable, strong, and surprisingly nimble.

But for small jobs, short distances, or rough terrain? You might be better off with something simpler.

3. Side Dump Body

The first time I worked with a side dump truck, we were on a road construction site.

We needed to lay down a long line of gravel without stopping. The driver pulled up alongside the trench, tilted the body, and dumped the load in one clean sweep. No reversing, no awkward turns. Just smooth, fast unloading.

If you’ve ever had to dump material where backing up is a problem, this setup might catch your interest.

A side dump body is a type of dump truck where the container tilts to the side—left or right—to release its load. Instead of lifting from the front like a rear dump, it uses hydraulic cylinders on the side to tip the bed. This design lets you unload material next to the truck while staying in position. It’s especially useful when space is tight behind you or when you’re working along a roadway or trench.

Most side dump bodies are built with steel for strength.

Some use aluminum for lighter weight, which can help you haul more without going over weight limits.

Advantages

So, why do some crews prefer side dumps?

Here’s what makes them practical:

- Fast unloading: No need to back up—just drive alongside and dump

- Lower tipping risk: The center of gravity stays lower than with a raised rear dump

- Great for spreading: Ideal for laying out gravel or backfilling long stretches

- Less risk of rollovers: Especially on uneven ground

If you’ve had issues with stability or space, this setup might solve both.

Specifications

When comparing side dump trucks, look at these numbers:

- Load volume: Usually between 20 and 30 cubic yards

- Dump angle: Around 50 degrees, which helps clear the bed fast

- Material options: Steel for heavy-duty use, aluminum for hauling lighter loads

- Body length: Ranges from 20 to 40 feet depending on your chassis and haul size

- Width: Typically 8.5 feet to stay within road limits

Limitations

Even with all the upsides, side dumps have a few things to think about.

- They need room: You need open space next to the truck to dump safely

- Not ideal for windy conditions: Lightweight materials like mulch can blow off-target

- More expensive: The design and hydraulics usually cost more than rear dump setups

Cost Factors

Here’s what you can expect if you’re looking at side dump bodies:

- New units: Typically range from $40,000 to $80,000

- Used units: Can go as low as $25,000, depending on age and condition

- Fuel: Slightly higher drag might impact fuel use over time

- Maintenance: Hydraulic systems and side pivot mechanisms need regular attention

Final Thoughts

In my experience, side dump trucks are a strong option for jobs that need speed, safety, and precision. If you’re laying road base, backfilling, or working along long stretches, they can really shine.

But they might not be worth it if your sites are tight, your loads are light, or your budget is stretched thin.

And if you’ve figured out that your job calls for more than an off-the-shelf solution, you’re not alone.

At Rhinotrail, we build dump trucks that match your work, not just the specs on paper. From dump bodies to flatbeds, tankers, and even low-beds, we help you get the exact trailer you need to move your business forward.

4. Bottom Dump (Belly Dump) Body

I still remember working a highway paving job where timing was everything. We needed to spread gravel quickly, evenly, and without stopping. That’s when I saw the value of a bottom dump body. It moved forward while releasing material in a clean line beneath the trailer, no need to stop, no piles, just a smooth windrow.

A bottom dump body, often called a belly dump, is built with a clamshell-style gate located underneath the trailer. It releases material straight down while the truck is moving, creating a long pile known as a windrow.

Key Advantages

So, why might you choose a bottom dump body over a rear or side dump?

Here are a few reasons:

- Great for precision spreading of aggregates and road base

- You can dump while driving, which saves time on large jobs

- The low center of gravity adds stability during unloading

- Less risk of tipping, especially on flat surfaces

If you’re in road construction or site prep, this design can seriously speed things up.

Specifications

Here’s what to look for when evaluating a bottom dump body:

- Load volume: 20 to 26 cubic yards

- Gate size: Often around 64 inches by 106 inches

- Material options: Steel for durability, aluminum for lighter hauls

- Dump mechanism: Pneumatic or hydraulic, depending on the model

- Length: Commonly 30 to 40 feet, depending on capacity

Limitations

But it’s not perfect for every site. There are some limitations:

- Not ideal for off-road or rough terrain where forward motion is limited

- Works best with loose, dry materials like gravel or sand

- Requires space to move forward while dumping, can’t be used in tight areas

Cost Factors

Before committing, consider the full cost:

- New bottom dump bodies: Usually range from $50,000 to $100,000

- Used options: Can go as low as $25,000

- Fuel usage: May be slightly higher if you’re constantly moving during unloading

- Maintenance: The gate system needs regular checks to avoid jams or leaks

If your work is fast-paced and spread-focused, the investment often pays for itself in saved time.

Final Thoughts

Bottom dump bodies are a strong option for jobs that need speed and clean delivery especially in road building or site prep. But they may not be worth it for uneven sites, sticky materials, or places without enough space to roll forward while dumping.

5. Articulated Dump Body

An articulated dump body is built to mount on a frame that pivots at the center. The body itself is similar to a standard rear dump, but it’s paired with a chassis designed for flexible movement. That flexibility makes it ideal for off-road jobs where tight turns and steep inclines are common.

The body tilts backward to unload material, just like a conventional rear dump. Most are made of high-tensile steel to handle heavy, abrasive loads like rock, ore, or debris.

Key Advantages

What sets articulated bodies apart? It’s the way they handle tough ground.

Here’s why they work so well off-road:

- The body stays stable on uneven terrain

- High dump angles help clear out heavy material fast

- You can carry large loads without risking rollover

- Good for mining, quarries, and logging roads

If you’ve ever struggled to dump material on a steep slope, you’ll appreciate how this design holds up.

Specifications

You’ll want to keep an eye on a few specs:

- Load volume: Often ranges from 22 to 45 cubic yards

- Dump angle: Around 65 to 70 degrees for full material clearance

- Material options: Heavy-duty steel to resist denting and wear

- Body length: Typically 16 to 20 feet

- Wall thickness: Often 0.25 inches or more, depending on the model

Limitations

Still, these aren’t made for every job.

- Not a good fit for tight urban job sites

- Heavier bodies mean more fuel use, especially over long distances

- The design adds cost to maintenance and initial purchase

Cost Factors

Be ready for a higher price tag:

- New articulated dump bodies: Often cost $300,000 to $600,000 (including truck chassis)

- Fuel: Higher consumption due to weight and power

- Maintenance: Includes hydraulics, hinge points, and heavy-duty reinforcements

This isn’t a light-duty investment. But it might be the only body that handles your site.

Final Thoughts

If you’re hauling heavy material over rough terrain, articulated dump bodies are a strong option. But they may not be worth it for smaller jobs, paved roads, or sites with limited space.

6. Off-Highway Dump Body

Working on large-scale mining projects, I’ve seen how essential it is to have equipment that can handle massive loads and tough terrains. The off-highway dump body is designed specifically for such demanding tasks.

An off-highway dump body is built for serious work. It’s mounted on massive trucks that operate in off-road environments like quarries, mines, and large-scale earthmoving sites. The body is designed to tilt backward, dumping heavy loads from the rear.

Most off-highway bodies are made from thick, high-strength steel. They need to take abuse, abrasive rock, jagged debris, and repeat loading cycles that would wreck lighter materials.

Key Advantages

So why use this type of body instead of a standard dump? Here’s what stands out:

- Built for extreme durability, especially in mining or heavy construction

- Can carry very large loads, which cuts down on trips

- Handles rough, uneven terrain without tipping or cracking

- Designed for long-term use under high pressure

Specifications

These bodies aren’t small. Let’s break down the typical specs:

- Load volume: 40 to over 100 cubic yards

- Material options: Mostly steel, with thick walls for extra strength

- Dump angle: Around 45 to 49 degrees

- Wall thickness: Often 0.5 inches or more

- Body length: Usually 20 feet or longer

Limitations

Even tough gear has its limits. Off-highway dump bodies aren’t for everyone:

- Not legal on public roads due to their size

- Expensive to run and maintain

- Need lots of space to turn, load, and dump

I’ve seen a few contractors rent one for small sites only to realize it was overkill and hard to maneuver.

Cost Factors

These dump bodies come with a high price tag. Here’s what to expect:

- Initial cost: $500,000 to over $1 million (usually includes the truck itself)

- Fuel: High consumption due to weight and power

- Maintenance: Big machines mean bigger repair bills especially for hydraulics and structural wear

Final Thoughts

An off-highway dump body is a strong option for mining, quarries, or other rugged environments. But it may not be worth it for smaller sites, paved roads, or short hauls.

7. Semi-Trailer End Dump Body

A semi-trailer end dump body is a container mounted on a trailer that can be detached from the tractor. It unloads by lifting from the front using a hydraulic system, dumping material out the rear.

These bodies are usually made from steel or aluminum. Steel offers durability for heavier, abrasive loads. Aluminum keeps the weight down so you can haul more legally without going over road limits.

Advantages

Here’s why this body type is useful for long-haul or high-volume jobs:

- Hauls larger volumes than straight-body trucks

- Detachable trailer gives flexibility for different tractor heads

- Quick unloading with rear tilt saves time

- Can move across highways and city roads legally

If you need to haul bulk materials over long distances, this setup can simplify your job.

Specifications

Let’s look at the numbers you’ll need when comparing specs:

- Load volume: Usually 20 to 30 cubic yards

- Dump angle: Around 45 degrees

- Material options: Steel for strength, aluminum for weight savings

- Trailer length: Typically between 28 and 40 feet

- Wall thickness: Steel bodies about 3/16 inch, aluminum around 1/4 inch

Ever struggled with a load that was too big for a standard dump? This body helps you move more without needing multiple trips.

Limitations

There are trade-offs with any setup. Here are a few challenges to keep in mind:

- Higher tip risk when dumping on uneven ground

- Less maneuverable than a rigid-body dump, especially in tight job sites

- Requires a flat, stable surface for safe unloading

Cost Factors

Here’s a breakdown of typical costs:

- New body: $30,000 to $70,000

- Fuel impact: Heavier loads and longer trailers mean more fuel

- Maintenance: Regular checks on hydraulics, welds, and trailer components are key

Over time, the savings from fewer trips can offset the higher upfront cost, especially on long hauls.

Final Thoughts

Semi-trailer end dump bodies are a strong option for moving large amounts of material across distances. But they may not be worth it if your jobs are short, your sites are tight, or you’re often on uneven ground.

8. Haul Dump Body

A haul dump body is a large, heavy-duty container that sits on top of an off-road dump truck. You’ll usually find it working in harsh environments like mining pits, rock quarries, or large earthmoving sites. These bodies aren’t used for road work or city hauling. They’re designed strictly for rugged, off-road use where loads are massive and terrain is brutal.

The body is built to tilt from the front, which lets the material slide out the back during dumping. It’s a rear-dump style, but much bigger and tougher than what you’d see on a standard dump truck.

Advantages

Let’s walk through what makes this body useful in the field:

- Massive load capacity: Designed for heavy-duty hauling

- High strength: Withstands constant contact with sharp and abrasive materials

- Built for rough terrain: Stable even on uneven ground

Specifications

Looking at the numbers helps make sense of its size:

- Load volume: 40 to over 100 cubic yards

- Material: High-strength steel

- Dump angle: Typically between 45 and 49 degrees

- Wall thickness: Around 0.5 inches or more

- Length: Often 20 feet or longer

Limitations

There are a few things that could make this body a poor fit:

- Not street legal: Strictly for off-road jobs

- Fuel use is high: Big body, big burn

- Requires space: Hard to operate in tight job sites

Cost Factors

With this kind of strength comes higher cost:

- Purchase price: $500,000 to over $1 million (truck and body combined)

- Fuel: Heavy loads equal heavy fuel use

- Maintenance: More wear means more upkeep—especially hydraulics and welds

Final Thoughts

A haul dump body is a strong option for heavy, off-road hauling like mining or large-scale excavation. But it may not be worth it for light materials or jobs with limited space.

9. U-Shaped Dump Body

A U-shaped dump body looks exactly how it sounds: the inside of the body is shaped like the letter “U.” Unlike traditional box-style dump bodies that have flat bottoms and squared-off corners, this one is rounded—like a half-pipe.

Why does that matter?

Because that curve changes how material moves. Instead of getting stuck in corners or packed into edges, the load naturally slides down the center when it’s time to dump. Think of how water flows through a curved pipe instead of a box. The same idea applies here.

It still dumps like a standard rear-loading body: the front of the body lifts up using hydraulics, and the material slides out the back. But because of the shape, unloading is faster and cleaner.

These dump bodies are built using either:

- Steel is used when durability matters more like with gravel or abrasive materials.

- Aluminum is lighter, so it helps you carry more without going over weight limits, especially useful in jobs where every pound counts.

I once watched a team switch from a square-style body to a U-shaped one on a project hauling wet clay. The difference was huge. Before, every dump left clumps stuck to the bed. With the U-shape, the material slid right out, no shovels, no delays.

So, if you’re dealing with materials that stick, clump, or need smooth flow, this design isn’t just different, it’s smarter.

Advantages

What makes this body worth considering? Here’s what it does well:

- Smoother unloading: Material slides out with less sticking

- Faster cycle times: Less cleanup between loads

- Better balance: Lower center of gravity adds stability while driving

If you’ve ever had to knock out stuck loads with a shovel, you’ll appreciate this design.

Specifications

Pay attention to these numbers when comparing models:

- Load volume: 20 to 40 cubic yards

- Material options: Steel or aluminum

- Dump angle: 45 to 50 degrees

- Body length: 18 to 24 feet

- Wall thickness: Steel about 3/16 inch, aluminum around 1/4 inch

Limitations

There are a few situations where this body might fall short:

- Less room for irregular debris: Not ideal for bulky demolition materials

- Can raise center of gravity when full: Affects stability if overfilled

- Cost: Slightly higher upfront compared to box-style bodies

Cost Factors

So what does this setup cost?

- New bodies: Around $30,000 to $70,000

- Fuel: May save some cost with aluminum builds

- Maintenance: Easier to clean, but still needs routine inspections for cracks and wear

Final Thoughts

U-shaped dump bodies are a strong option for hauling materials that tend to stick or pile unevenly. But they may not be worth it for bulky debris or jobs where material shape varies load to load.

Conclusion

Finding the right dump body isn’t just about dimensions but matching your equipment to the way you actually work. It’s about understanding your materials, your terrain, and your time.

I’ve been on job sites where using the wrong body type caused delays that lasted for days. But I’ve also seen what happens when the right body rolls in.

That’s why I created this guide, to give you a clear, practical comparison. So you’re not left guessing.

Now it’s your move.

Don’t wait for the wrong body to show you its limits. Start planning now and choose the option that works best for your job and your team.

And if you’re still weighing options or unsure where to begin, contact us today. We’ll walk through it with you and help you make the smart call.