I still remember one of the first times I rode in a fully loaded dump truck on a rough site. Every bump felt like a hard hit. The whole truck bounced, and so did I.

The job got done, but my back didn’t feel right for days. Back then, I didn’t know how much the suspension system mattered.

Since then, I’ve worked with many dump trucks. I’ve seen how the right suspension can make a big difference—not just in ride comfort, but in how long your truck lasts, how much you can haul, and how safely you can do the job.

So if you’re trying to figure out which suspension works for your dump truck, I get where you’re coming from.

In this article, I’ll walk you through 9 different types of dump truck suspension systems. I’ll explain how each one works, where it’s best used, and what kind of jobs it can handle.

By the time you’re done reading, you’ll have the knowledge to choose the right suspension for your work.

Let’s dive in!

Comparison Table

Before diving into all the deep details, here’s a quick look at how the 9 dump truck suspension types stack up.

Use this table to get a feel for what each one offers—and where it fits best.

| Suspension Type | Key Features | Best Used For | Maintenance Focus |

| Leaf Spring | Multi-leaf steel, strong load support, simple mechanical setup | Heavy loads, rough terrain, construction, mining | Cracks, rust, sagging springs, U-bolt tightness |

| Air Ride | Air springs, adjustable ride height, smooth and quiet ride | Highway, sensitive cargo, light to medium hauling | Air leaks, bag cracks, compressor and valve inspections |

| Walking Beam | Pivoting beam, high articulation, great traction and load sharing | Off-road jobs, logging, uneven terrain, heavy hauling | Greasing pivot, bushing wear, cracks, axle alignment |

| Rubber Block | Rubber shock absorption, quiet operation, no air or hydraulics | Urban delivery, regional routes, consistent heavy loads | Rubber wear, height imbalance, mount checks, cleaning |

| Chalmers | Rubber springs + beam combo, shock reduction, balanced load control | Mixed terrain, fleet trucks, construction | Rubber damage, beam alignment, pivot grease, bracket wear |

| Hendrickson | Tri-functional bushings, load equalization, reliable over time | Fleet use, mixed roads, heavy-duty work | Bushing checks, air (if equipped), beam and mount wear |

| Torsion Bar | Compact design, steel twist bar, adjustable stiffness | Light to medium loads, city routes, smaller trucks | Bar rust/cracks, ride height issues, joint lubrication |

| Hydraulic | Fluid-based cylinders, height control, fast response to shifting loads | Specialty hauling, uneven loads, custom applications | Fluid levels, leaks, pump/valve maintenance, dirt removal |

| Equalizing Beam | Pivoting steel beam, distributes weight evenly, fully mechanical | Quarry, landfill, off-road dump work | Beam greasing, bolt/bushing checks, undercarriage cleaning |

Now let’s explore each suspension type in more detail.

1. Leaf Spring Suspension

Leaf spring suspension is one of the oldest types still used on dump trucks today. And for good reason. It’s simple, tough, and gets the job done.

A leaf spring is a long, flat piece of metal—usually steel—stacked in layers. These layers flex when your truck hits bumps or carries a heavy load. The more weight on the truck, the more the springs compress to support it.

I’ve seen these used on trucks hauling gravel, sand, and soil every day. One driver told me, “They’re not fancy, but they don’t quit.” And he was right.

Key Features

- Multi-Leaf Construction: Uses layers of steel to evenly distribute weight and absorb shock.

- Load Support: Strong enough to carry very heavy loads without sagging.

- Flexibility Under Pressure: Springs bend with the terrain, giving your truck a stable base.

- Simple Mechanics: No air lines or sensors—just steel and movement.

- Consistent Performance: Keeps doing the job even under tough daily use.

Best Used For

- Heavy-Duty Hauling: Great for dirt, rock, and bulk materials.

- Off-Road Applications: Handles bumps, slopes, and rough ground well.

- Construction and Mining Sites: Built to work in hard, uneven environments.

Maintenance Needs

- Inspect for Cracks: Look for any broken or split leaves—especially after long jobs.

- Watch for Rust: Rust around the spring eyes or mounts can lead to failure.

- Check for Sagging: Uneven truck height could mean one side’s wearing out.

- Tighten U-Bolts: Loose bolts can cause movement and premature wear.

Does your worksite beat up your trucks?

Leaf spring suspension may not be fancy, but it’s tough, reliable, and ready for heavy work.

2. Air Ride Suspension

The first time I rode in a dump truck with air ride suspension, I could tell the difference right away. The ride was smooth—even over potholes. The cab didn’t shake. The road stayed steady. I remember thinking, “This is what comfort feels like in a truck.”

Air ride suspension uses air-filled rubber bags, also called air springs, instead of steel springs. These bags adjust to the load and road. The result? A smoother ride and better protection for what you’re hauling.

Key Features

- Air Springs: Uses compressed air in rubber bellows to support the truck and absorb shock.

- Adjustable Ride Height: Can raise or lower to match dock height or improve clearance.

- Smooth Ride Quality: Reduces vibrations in both cab and trailer.

- Less Shock on Cargo: Protects fragile or high-value loads during transport.

- Self-Leveling System: Some systems adjust automatically based on the load.

Best Used For

- Long-Distance Hauls: Great for highways and smoother roads.

- Light to Medium Loads: Performs well without overloading the system.

- Cargo That’s Sensitive to Movement: Like electronics, glass, or food products.

Maintenance Needs

- Check for Leaks: Air lines and bags can leak over time.

- Inspect Air Bags: Look for cracks or worn spots, especially near mounting areas.

- Monitor Air Compressor: This powers the system—if it fails, the whole ride suffers.

- Replace Valves as Needed: Height control valves can stick or wear out.

If you’re hauling sensitive goods or want a smoother ride for your drivers, air ride suspension is worth considering. It’s not just about comfort—it’s about control.

3. Walking Beam Suspension

If you’ve ever worked on a dump truck that hauls over uneven ground, you’ve probably seen walking beam suspension in action.

Walking beam suspension uses two axles connected by a beam that pivots in the center. This design helps keep all wheels on the ground, even on rough terrain. It spreads weight evenly and offers more traction where it’s needed most.

This isn’t a soft, smooth ride system—but it’s strong and steady.

Key Features

- Equal Load Distribution: Beam design spreads the weight across both axles.

- Great Traction: Keeps wheels grounded over rocks, mud, and hills.

- High Articulation: Axles move independently for better control on uneven ground.

- Heavy-Duty Build: Built for serious loads and rugged sites.

- No Air or Hydraulics: Purely mechanical, which means fewer things to fail.

Best Used For

- Off-Road Hauling: Ideal for mining, logging, and rugged construction areas.

- Extreme Terrain: Performs well on slopes, deep ruts, and rocky roads.

- Heavy Loads: Handles big, demanding hauls with ease.

Maintenance Needs

- Grease Pivot Points: Keep that central beam moving freely.

- Inspect for Wear: Bushings and beams can wear out under high pressure.

- Check for Cracks: Look at stress points around mounts and connections.

- Monitor Axle Alignment: Misalignment can cause uneven wear on tires.

There’s something about watching a truck glide through deep ruts and rocky slopes without slipping—it tells you the suspension is doing its job. If your day-to-day work means dealing with harsh ground and heavy loads, walking beam suspension gives you the kind of confidence you can count on.

It’s one of those systems that just works—no fuss, no drama, just power and balance when you need it most.

4. Rubber Block Suspension

Rubber block suspension doesn’t get talked about as much as air or leaf spring systems, but it deserves some attention. The first time I worked with one, I was surprised by how quiet and steady the ride felt. No air lines, no steel stacks—just solid rubber doing the work.

This system uses solid rubber blocks instead of springs or air bags. The rubber compresses when the truck hits a bump, helping absorb shock and reduce bounce. It’s simple, tough, and built to handle heavy work without a lot of parts.

Key Features

- Rubber Compression: Blocks absorb shock and vibration through natural rubber flex.

- Low-Maintenance Design: No air lines, valves, or fluid systems to monitor.

- Quiet Operation: Reduces noise and vibration, especially on paved surfaces.

- Durable Build: Rubber resists wear, rust, and corrosion better than metal springs.

- Stable Load Handling: Stays strong under heavy loads, even over time.

Best Used For

- Regional Hauling: Great for short to medium routes with mixed road conditions.

- Urban Delivery: Smooth on pavement and resistant to frequent stopping and starting.

- Heavy-Duty Work: Holds up well under consistent, high-weight jobs.

Maintenance Needs

- Inspect Rubber Blocks: Look for cracks, hardening, or missing chunks.

- Check Mounting Points: Bolts and brackets can wear down with time.

- Monitor Ride Height: Uneven height may signal worn-out rubber or loose connections.

- Clean Regularly: Dirt buildup can hide damage and wear.

Looking for something tough with less upkeep?

Rubber block suspension could be a smart choice—quiet, steady, and built to take the daily grind without slowing you down. Sometimes, simple really is better.

5. Chalmers Suspension

Chalmers suspension is one of those systems that strikes a balance between strength and flexibility.

This suspension system uses a combination of rubber springs and walking beams. The rubber provides cushion and absorbs shock, while the beams help balance the load between axles. It’s built for tough work but offers a smoother ride than basic mechanical systems.

Key Features

- Rubber Spring Design: Uses rubber components to reduce shock and road noise.

- Walking Beam Setup: Shares the load between axles, keeping all tires grounded.

- Strong Load Control: Handles shifts in weight during dumps and turns.

- Durable Frame Mounting: Built to stay stable under stress and vibration.

- Good Ride Stability: Offers a smoother experience than traditional steel-only suspensions.

Best Used For

- Construction Hauling: Great for dirt, rock, and asphalt jobs.

- On/Off-Road Routes: Handles well on both pavement and jobsite terrain.

- Fleet Use: Balanced enough for drivers who switch between load types.

Maintenance Needs

- Check Rubber Springs: Look for cracking or wear, especially around ends.

- Grease Pivot Points: Reduces wear and keeps the system moving freely.

- Inspect Beam Alignment: Misalignment can cause uneven tire wear.

- Watch Mounting Hardware: Loose bolts or damaged brackets can affect performance.

Ever wish your truck could ride smoother without losing strength?

Chalmers might be what you’re looking for—tough where it counts, but still kind to the driver behind the wheel.

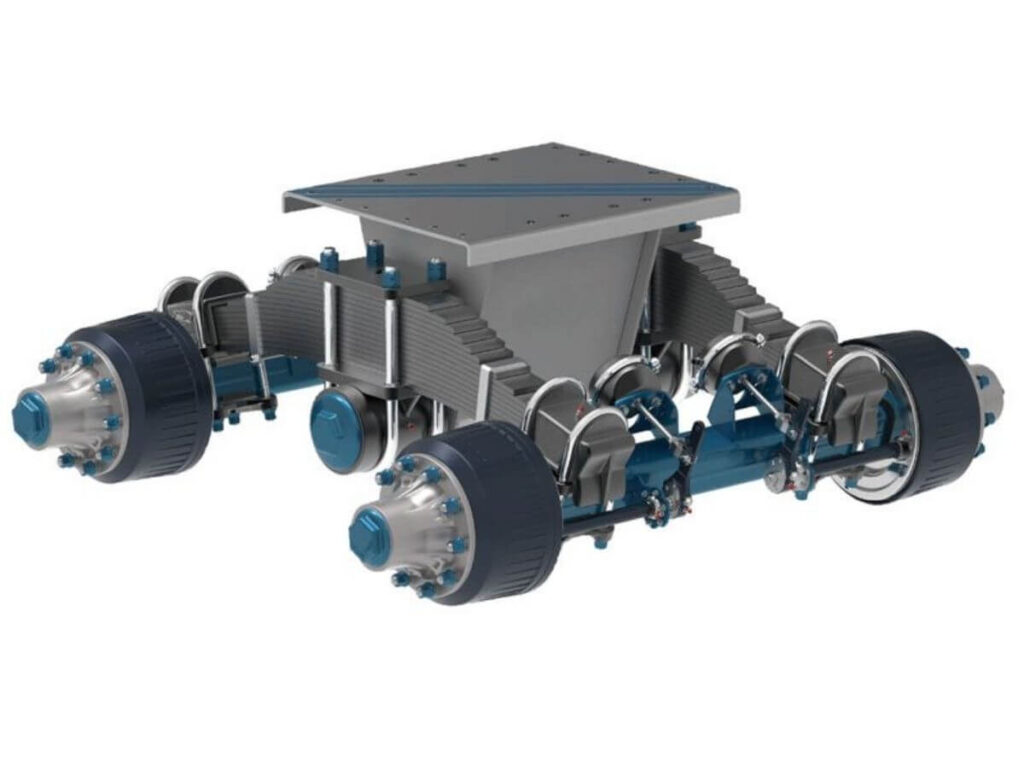

6. Hendrickson Suspension

Hendrickson suspension is known for being both strong and smart. Many models use a combination of tri-functional bushings, steel springs, and walking beams. The design spreads the load evenly and helps keep the truck stable—even under tough conditions.

It’s made for durability, but it doesn’t forget about ride quality.

Key Features

- Tri-Functional Bushings: Help reduce noise and cushion road shock.

- Load Equalization: Balances weight between axles for even tire wear.

- Durable Components: Built for high-impact, heavy-duty work.

- Flexible Options: Comes in several designs, including air and mechanical systems.

- Stable Performance: Keeps the truck level, even with uneven loads.

Best Used For

- Heavy-Duty Construction: Handles tough jobs and hard roads.

- Mixed Route Hauling: Works well on pavement, gravel, or rough access roads.

- Fleet Operations: Common in fleets for its long-term dependability.

Maintenance Needs

- Inspect Bushings: Cracks or wear can affect performance.

- Grease Suspension Points: Reduces friction and wear over time.

- Check for Leaks (Air Models): Air springs and lines should be checked regularly.

- Monitor Beam and Axle Mounts: Loose or damaged parts can affect alignment.

I’ve worked with plenty of trucks, but the ones running Hendrickson always seemed to hold up better and ride easier. If your days are long and the roads are rough, this suspension might just help you—and your truck—last a little longer out there.

7. Torsion Bar Suspension

Torsion bar suspension isn’t as common on dump trucks, but when it’s used right, it works well.

This system uses a steel bar that twists under pressure instead of bending like a spring. One end of the bar is attached to the frame, and the other connects to the suspension arm. When your wheel hits a bump, the bar twists and absorbs the impact.

It’s a clean design that works best in specific setups.

Key Features

- Torsional Flex: Absorbs shock by twisting rather than compressing.

- Compact Design: Takes up less space compared to leaf or air systems.

- Adjustable Stiffness: You can tune the ride feel by adjusting the bar.

- Lightweight System: Reduces vehicle weight for better fuel efficiency.

- Stable Ride Control: Works well for predictable road conditions.

Best Used For

- Light to Medium Loads: Ideal for smaller dump trucks or trailers.

- Paved Routes: Performs best on smoother surfaces.

- Urban Work: Great for tight spaces and frequent turns.

Maintenance Needs

- Check for Bar Wear: Look for rust or cracks at both ends.

- Inspect Mounting Points: Loose brackets can cause poor handling.

- Monitor Ride Height: Uneven stance may mean a worn or misaligned bar.

- Lubricate Joints: Keeps movement smooth and prevents metal-on-metal damage.

Ever feel like your truck doesn’t need heavy-duty gear for every job?

Torsion bar suspension might be just right—simple, space-saving, and smooth when the road’s not too rough. Sometimes less really is more.

8. Hydraulic Suspension

I first heard about hydraulic suspension from a mechanic who worked on specialty haulers. He told me, “It’s not for every job, but when it fits, it’s hard to beat.” That got me curious. Later, I got the chance to ride in one myself. The way it handled weight shifts and tight turns was something I hadn’t felt in other trucks.

Hydraulic suspension uses fluid-filled cylinders to absorb shock and control movement. Unlike springs or air bags, it works by pushing hydraulic fluid through valves to manage bumps, loads, and road angles. It’s smooth, steady, and responsive.

But it’s also more technical than most systems.

Key Features

- Fluid-Based Shock Absorption: Uses hydraulic oil to reduce impact and manage ride feel.

- Adjustable Ride Height: Lets you lift or lower the truck when needed.

- Strong Load Handling: Handles heavy and uneven loads with stability.

- Quick Response: Adjusts fast to changing road or load conditions.

- Great Balance: Keeps your truck steady even on uneven ground.

Best Used For

- Specialty Hauling: Great for oversized equipment or irregular loads.

- Jobs With Uneven Weight: Helps maintain level stance when loads shift.

- Mixed Terrain Work: Works well on pavement, gravel, or site roads.

Maintenance Needs

- Monitor Fluid Levels: Low fluid can cause poor performance.

- Inspect for Leaks: Hoses and seals wear over time.

- Keep it Clean: Dirt can block valves and damage internal parts.

- Service Pumps Regularly: These power the whole system and need routine checks.

Thinking of adding more control to your ride?

Hydraulic suspension might be the tool for that. It takes more care, but when you need precision and power—it’s worth the extra work.

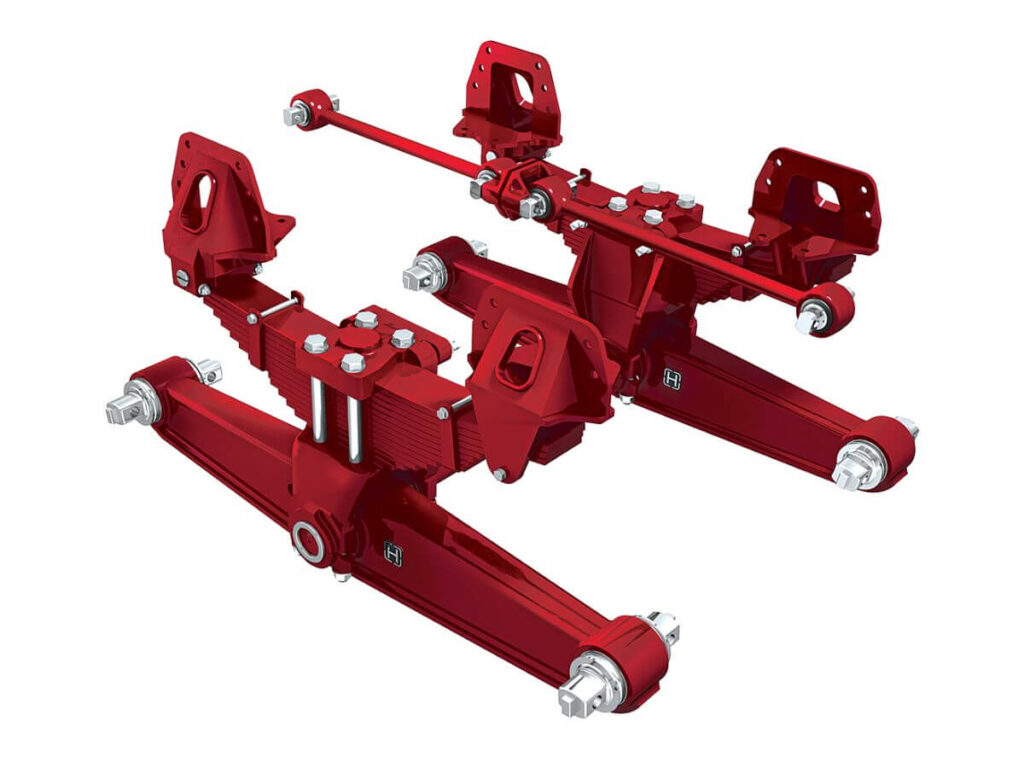

9. Equalizing Beam Suspension

Equalizing beam suspension uses a pivoting beam that connects two axles. When one wheel goes up, the other goes down. This helps keep both wheels on the ground and spreads the load between axles. It’s a mechanical system with no air or fluid involved—just solid steel and motion.

It’s a workhorse, plain and simple.

Key Features

- Load Sharing: Distributes weight evenly between axles.

- Pivoting Beam: Keeps tires in contact with the ground for better traction.

- Strong Structure: Built with solid steel, ideal for tough jobs.

- Good Stability: Reduces tilt and body roll over uneven surfaces.

- Simple Operation: No air lines, electronics, or hydraulic parts to manage.

Best Used For

- Off-Road Dump Work: Great for quarries, landfills, and dirt roads.

- Heavy Loads: Built to carry weight without sagging or bounce.

- Jobs With Uneven Ground: Keeps the truck stable through dips and ruts.

Maintenance Needs

- Grease Pivot Points: Regular greasing keeps the beam moving smoothly.

- Inspect for Wear: Look for cracks or rust at welds and mounting points.

- Check Bolts and Bushings: Loose parts can cause clunks or poor alignment.

- Clean the Undercarriage: Dirt buildup can hide early signs of damage.

Equalizing beam suspension might be the old-school solution that still delivers for rought jobs. It doesn’t talk back—but it keeps your wheels planted and your load steady.

Conclusion

That rough ride taught me something—suspension isn’t just about comfort. It’s about keeping loads stable and trailers running strong.

Now you’ve seen 9 types of suspension systems and where each one fits. Whether you’re hauling heavy, moving off-road, or covering long distances—there’s a setup for that.

At Rhinotrail, we build trailers that support your truck’s performance, not slow it down.

Contact us today and we’ll help you build the right solution!