Years ago, I failed a safety inspection.

Not because I ignored the rules.

But because I didn’t understand how my hydraulic brakes worked.

The system was fine—on paper. But I couldn’t explain it. I couldn’t spot the issue. I didn’t even know what to ask the mechanic.

If you’ve ever felt confused about how your trailer stops, I get it.

I’ve been there.

Since then, I’ve learned everything I could about hydraulic trailer brakes. And in this article, I’ll pass that on to you.

You’ll find simple explanations, real-world examples, and the info you need to use, maintain, and choose the right brake system.

So let’s dive in!

1. What Are Hydraulic Trailer Brakes?

If you’ve ever towed a heavy trailer, you know how important it is to stop smoothly and safely. That’s where hydraulic trailer brakes come in.

So, what are they?

In simple terms, hydraulic trailer brakes use fluid pressure to make the brakes work. When you press your brake pedal in the tow vehicle, it sends fluid through a line. That pressure moves parts inside the brake system and pushes the brake shoes or pads against the wheels.

That’s what slows the trailer down.

No wires. No motors. Just pressure from brake fluid.

Where You’ll See Them

You’ll often find hydraulic brakes on trailers that carry heavy loads like:

- Dump trailers

- Equipment haulers

- Low-bed trailers

- Construction and industrial trailers

I remember hauling a loaded dump trailer through a construction site. The trailer had hydraulic brakes. The stop was smooth—even with a full load of gravel. No sudden jerk. No noise. Just control.

That’s what hydraulic brakes are good at smooth, steady braking when the weight gets serious.

How They’re Different from Electric Brakes

Most trailers use either hydraulic or electric brakes.

Electric brakes use wires. They’re powered by your tow vehicle’s electrical system. When you press the brake, electricity moves magnets that press brake pads against the wheel.

Hydraulic brakes are different.

- No wires

- No magnets

- Just brake fluid and pressure

That’s why some drivers prefer them less delay, more natural feel, especially with heavier trailers.

In my experience, hydraulic brakes respond better when you’re going downhill or stopping a loaded trailer on wet ground. You feel like the trailer is working with you, not dragging behind or fighting the tow vehicle.

If you’re new to trailers, the word “hydraulic” might sound technical. But really, it’s just a way to say: You press the pedal. The fluid moves. The trailer stops.

Simple. Reliable. Especially under pressure.

And once you understand that, the rest of the system starts to make a lot more sense.

2. Why Hydraulic Brakes Matter for Heavy Loads

If you’ve ever hauled a full trailer down a steep slope, you know how fast things can go wrong.

I’ve been there.

My trailer was packed with steel pipes. The hill was wet. My hands were tight on the wheel, foot on the brake and I could feel the weight pushing hard from behind.

That day, I was thankful for hydraulic brakes. They didn’t lock up. They didn’t jerk. They just slowed the trailer down smoothly and steadily.

Let’s talk about why hydraulic brakes are built for heavy jobs like that.

Better Control for High Weight Capacities

Hydraulic brakes handle pressure well. Literally.

They use brake fluid to push against the braking parts. That pressure gives you a more even response even when you’re carrying tons of weight.

You’ll see these brakes often on:

- Dump trailers

- Fuel tankers

- Low-bed trailers

- Equipment haulers

At Rhinotrail, we build trucks and trailers designed for these tough jobs. And we know that when you’re hauling heavy, shifting loads, your brake system needs to keep up—without sudden stops or grabbing.

Electric brakes can sometimes feel too sharp or delayed under a big load. Hydraulic brakes tend to be more balanced. You press the pedal. The trailer slows down smoothly.

Safety on Slopes and Rough Terrain

Not every road is flat. Not every job is easy.

On mountain roads, gravel paths, or steep construction sites, your trailer’s brakes do more than stop—they help keep you in control.

Hydraulic brakes shine in these situations.

- They apply pressure gradually

- They help reduce trailer sway

- They’re less likely to lock up the wheels

I remember helping a buddy haul a fuel tank through a mining area. It was rocky, uneven ground. His trailer had electric brakes and they kept locking up. My trailer, with hydraulic brakes, held steady. No skidding. No drama.

That’s the difference.

When you’re pulling heavy loads through rough spots, you don’t just want to stop you want to stay stable.

Hydraulic brakes give you that confidence. And that peace of mind makes all the difference at the end of a long haul.

3. Key Components of a Hydraulic Trailer Brake System

When I first opened up a hydraulic brake system, I was surprised by how simple it looked—and how much each part mattered.

If you’ve never seen one before, don’t worry. I’ll break it down part by part. You’ll see how everything works together to stop your trailer.

Let’s start at the front and move to the wheels.

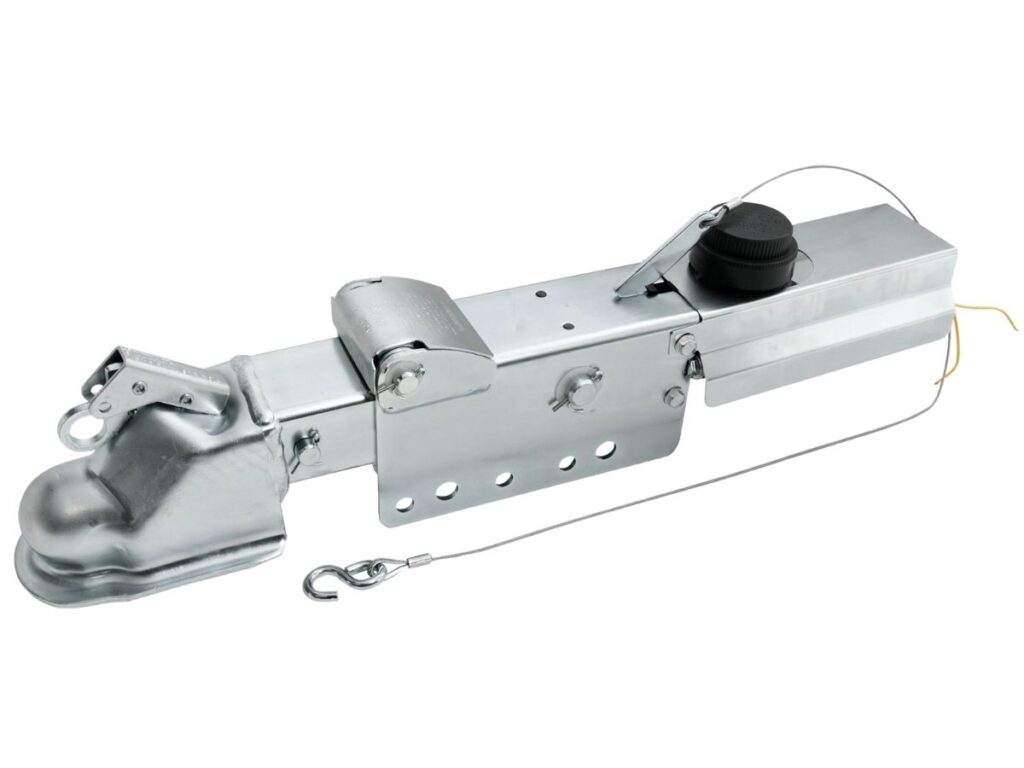

Surge Actuator (or Brake Actuator)

This is the brain of the system. You’ll find it mounted on the trailer tongue, right near the hitch. It’s built to sense when your tow vehicle slows down.

Here’s what happens:

- You hit the brake pedal

- Your vehicle slows

- The trailer pushes forward slightly

- That pressure compresses the actuator

Once it compresses, it sends brake fluid down the lines. No electronics. Just movement and pressure. Simple and effective.

I remember testing mine after loading a heavy mini-excavator. The actuator kicked in as soon as I eased off the gas. No jerking. Just smooth braking.

Brake Lines

These are the veins of the system. They carry hydraulic fluid from the actuator to the brakes on each wheel. For heavy-duty or off-road trailers, you’ll want lines that are:

- Thick

- Corrosion-resistant

- Built to handle vibration

If a line leaks or cracks, the whole system suffers. I always check mine before a job, especially after rough terrain or winter storage.

Hydraulic Brake Assembly

This is where stopping power happens. The assembly includes either drum brakes or disc brakes, depending on your setup. When the fluid reaches this part, it pushes pistons, which apply force to either:

- Brake shoes (drum)

- Brake pads (disc)

That force presses against the wheel, slowing it down.

Brake Fluid Reservoir

Think of this as the system’s supply tank. It holds the fluid that moves through the brake lines. If it runs low, your brakes won’t work properly. Always keep an eye on it. Low fluid can mean a leak—or that it’s time for a refill. A quick check takes seconds and can save you a world of trouble.

Backing Plate and Wheel Cylinder

These parts sit inside the drum brake. The backing plate holds everything in place springs, shoes, and pistons. The wheel cylinder pushes the brake shoes out when fluid pressure reaches it. That outward motion is what stops the wheel from spinning. Simple. Mechanical. And reliable if you take care of it.

Every piece matters. And once you see how they connect, you’ll feel more confident working with your trailer—whether you’re fixing a line or just topping off fluid before a long haul.

4. How Hydraulic Trailer Brakes Work

If you’ve ever hauled something heavy—like an excavator on a low-bed trailer—you know how important it is to stop smoothly, especially going downhill.

I remember a trip through a mountain pass. Long slope. Tight turns. Wet pavement. I kept one hand steady on the wheel, the other ready on the trailer brake. But honestly, the hydraulic system did most of the work. And it made all the difference.

Here’s how that braking process works, step by step.

- Step#1 The Tow Vehicle Slows Down: You press the brake pedal in your truck. The truck starts to slow. But the trailer still wants to keep moving forward. That’s where the system begins to respond.

- Step#2 The Actuator Compresses: As the trailer pushes forward, it presses against the actuator on the trailer tongue. This compression is what activates the braking system. It’s a physical force—no electricity needed.

- Step#3 Brake Fluid Moves Through the Lines: The actuator has brake fluid inside. When it compresses, it pushes that fluid through the brake lines. These lines run all the way to the wheels of your trailer.

- Step#4 Fluid Reaches the Brake Assemblies: Each wheel has a brake assembly—either drum or disc. When the fluid gets there, it creates pressure inside the wheel cylinder.

- Step#5 Brake Shoes or Pads Press Outward: That pressure pushes the brake shoes (in a drum system) or brake pads (in a disc system) against the wheel. The harder the pressure, the stronger the braking force.

- Step#6 Friction Slows the Trailer: As the shoes or pads press against the wheel, friction builds up. That friction is what actually slows the trailer down. No sharp jerks. No sudden grabs. Just smooth, gradual stopping, especially helpful with a full load on uneven ground.

Understanding this chain reaction helps you know what’s happening under your trailer every time you stop.

It’s not magic. It’s pressure, movement, and friction—all working together.

And once you see how each step flows into the next, you’ll know how to spot problems, make small fixes, and trust your brakes on every job.

5. Hydraulic Brakes vs. Electric Brakes

I’ve used both hydraulic and electric brakes over the years. And I’ve seen what works best in different situations.

Once, I was hauling a light cargo trailer with electric brakes, easy trip, flat roads. No problem at all. Another time, I was towing a heavy low-bed trailer loaded with machinery. I needed smooth control on steep slopes. That’s when I trusted hydraulic brakes.

Each system has strengths. And each has limits.

Here’s a simple comparison to help you decide what fits your trailer and your work.

| Feature | Hydraulic Brakes | Electric Brakes |

| How it Works | Uses brake fluid to transfer pressure from the actuator to the brakes | Uses electricity to activate brake magnets that apply pressure to the wheels |

| Control Feel | Smooth, gradual braking—especially with heavy loads | Can be more sudden or uneven, depending on controller setup |

| Best For | Heavy-duty trailers (dump trailers, equipment haulers, low-beds) | Lighter trailers (cargo, utility, camper trailers) |

| Power Source | Works independently—no power from the tow vehicle needed | Needs a working brake controller and battery from tow vehicle |

| Setup | More mechanical—fewer electronics, but needs good fluid maintenance | Easier to wire and install if vehicle already has a brake controller |

| Terrain Handling | Great on slopes, rough ground, and off-road jobs | Performs well on flat roads and highway conditions |

| Maintenance | Needs fluid checks, occasional bleeding, and part replacements | Needs wiring checks, magnet wear monitoring, and brake controller tuning |

| Common Issues | Leaks, air in the lines, worn seals | Wiring faults, weak magnets, controller failure |

In my experience, if you’re hauling serious weight, go hydraulic. The braking feels more natural, especially on tricky terrain. But if you’re pulling lighter loads and want simple wiring, electric brakes can work just fine.

The key is knowing your trailer, your route, and your load.

Once you match the right brake system for your job, the road feels a lot safer.

6. Common Problems and Troubleshooting Tips

Hydraulic trailer brakes work hard. And over time, they wear down—just like any other part of your trailer.

I learned this the hard way.

I was hauling a load of gravel on a hot day. The trailer didn’t stop like it used to. It felt slow. Soft. Almost like the brakes weren’t even there. That trip taught me a lesson don’t wait until something fails.

Here are a few common brake problems and what to look for before they get worse.

Brakes Feel Weak or Slow to Engage

This is a red flag. If your brakes feel soft, there’s probably a pressure issue in the system. Two common causes:

- Air in the brake lines: If air gets into the system, the pressure won’t build right. You might need to bleed the brakes to remove the air.

- Low or dirty brake fluid: Old fluid gets thick or full of debris. That can slow down how the system responds.

Fixing this early can save you from a brake failure on the road.

Brake Fluid Leaks

Leaks are serious. If you notice wet spots around fittings or lines, check:

- Brake hoses

- Actuator seals

- Connection points at the wheels

Even a small leak means less pressure and slower braking. If the leak is from a crack or worn part, replace it right away. Don’t wait.

Trailer Pulls to One Side During Braking

This one can be hard to spot until it happens at the wrong time.

If your trailer jerks to one side when braking, it usually means:

- One side is braking harder than the other

- A piston may be stuck

- Brake shoes or pads might be worn unevenly

I’ve seen this on a low-bed trailer with older brakes. One side grabbed it harder than the other. It felt like the trailer was trying to steer itself. A quick look showed one wheel cylinder was sticking.

Squeaking or Grinding Noise

Don’t ignore noise. It’s often the first sign that your brake parts are worn.

- Squeaking = early wear

- Grinding = metal-on-metal contact

By that point, you might need new shoes, pads, or a full brake service.

Quick Tip: Set a Maintenance Schedule

If your trailer works hard, heavy loads, long hauls, rough terrain check the brakes every 3 to 6 months.

- Inspect the fluid

- Look at the pads or shoes

- Check for leaks or cracks

You don’t have to be a mechanic to spot trouble early. Just take the time. A few minutes in the shop can prevent a big problem on the road.

And in my experience, those small checks often make the biggest difference.

7. Maintenance Tips to Keep Brakes Working Safely

If there’s one thing I’ve learned from years on the road, it’s this—don’t wait until your brakes tell you something’s wrong.

By then, it’s usually too late.

Hydraulic trailer brakes are strong, but they need regular care. A few small checks can keep your trailer safer, your stops smoother, and your repair bills a lot lower.

Here’s what I’ve found works best.

Regular Checks

This is where most folks slip up. You get busy. You skip a check. Then a small issue turns into a big one.

Here’s what to look for:

- Brake fluid level: Check it every month. Low fluid can mean a leak or worn parts.

- Leaks or corrosion: Inspect hoses and connections. Look for wet spots, rust, or cracked lines.

- Brake test: Before every haul, test your brakes. Pull forward slowly and hit the brakes. Feel for delay, noise, or pulling.

I do these checks before any long trip—especially with heavy loads. It takes 5 minutes. It gives peace of mind.

Brake Bleeding

Bleeding your brakes clears out trapped air. Air in the system means less pressure. Less pressure means weaker brakes. You should bleed your hydraulic brakes:

- At least once a year

- Anytime you replace or top off brake fluid

If you’ve never done it before, it’s not too complicated. But it helps to follow a guide or have someone pump the actuator while you open the bleed valve.

There are great visual guides online. Or ask a mechanic to walk you through it the first time.

Replace Fluid Periodically

Brake fluid doesn’t last forever. It picks up moisture over time, and that weakens performance. Most trailer manufacturers recommend:

- Replace fluid every 1 to 2 years

- Use DOT-rated brake fluid as listed in your trailer’s manual

I made the mistake once of topping off with the wrong fluid. The system gummed up and took weeks to fix. Since then, I only use what the manual says—and I mark the date on a sticker inside my trailer toolbox.

Good brakes aren’t about luck. They’re about good habits.

You don’t need fancy tools or a shop. Just a little time and attention. A regular check here, a fluid swap there—and your trailer will stay safe, stop smooth, and last longer.

Conclusion

Hydraulic trailer brakes don’t have to be confusing.

Now you know:

- What they are

- How they work

- How to keep them in shape

From steep hills to tight jobsites, this system gives you power and control. But only if you maintain it.

You’ve got the tools now. And knowledge.

So the next time your trailer is loaded down, you won’t be guessing. You’ll be ready.

Where will you start? What’s the first habit you’ll build?

If you’re still unsure, contact us today. We’ll help you figure it out.