Before I knew how to use a dump truck, I made a mistake that nearly cost a whole day of work.

I unloaded on uneven ground, and the truck shifted just enough to get stuck.

That’s when I realized—learning before doing matters.

Since then, I’ve been around many trucks. I’ve helped people figure out the right way to use them. I’ve also seen what happens when those steps get skipped.

This article gives you the full process.

You’ll learn how to load material safely, haul without problems, and unload the right way.

By the end, you’ll have a solid understanding of how to run a dump truck with care.

So let’s get down to it!

1. What Is a Dump Truck?

The first time I saw a dump truck in action, I was standing at a job site watching a load of gravel get dropped in seconds. The driver didn’t say much—he backed up, pulled a lever, and the whole load slid out like it was nothing. That moment made me realize how useful these trucks really are.

A dump truck is a heavy vehicle made for moving and dumping loose materials like dirt, gravel, sand, or crushed rock. What makes it different from a regular truck is this: the bed lifts up using hydraulics, so the load slides out the back without needing extra equipment.

Its main job: carry a heavy load, then dump it fast and clean.

Dump trucks are used across many industries:

- Construction: for sand, gravel, or concrete debris

- Mining: to carry coal, rock, or waste

- Agriculture: to move soil, compost, or crops

- Industrial sites: to transport bulk raw materials or remove waste

If you need to move a lot of material and unload it quickly, this is the type of truck that gets it done.

How It Works

The truck bed is mounted on a frame that can tilt. This tilt is powered by hydraulic cylinders, which are like strong metal arms filled with pressurized fluid. When the driver activates the system, the front of the bed lifts up, and gravity does the rest—everything inside slides out the back.

It’s simple, but powerful.

At Rhinotrail, naturally, we build our dump trailers to handle this kind of work every day. Whether it’s fine sand or rough stone, the goal is the same: quick loading, smooth hauling, and clean unloading.

Learning how to use one safely starts with understanding what it’s built for. In the next section, we’ll walk through the steps you need to follow before you even start the engine.

2. Basic Components of a Dump Truck

When you’re learning to use a dump truck, one of the best things you can do is get to know its main parts. Every component plays a role in how the truck works, especially when hauling and dumping heavy loads.

Not sure what each part does? Don’t worry. Here’s a simple breakdown to help you understand what you’re working with:

- Truck Chassis: This is the main frame of the truck. It supports everything—the cab, engine, wheels, and the dump bed all sit on top of it. The chassis has to be strong because it holds the full weight of the truck and whatever material you’re hauling.

- Dump Bed (or Body): This is the large open box on the back where you load materials like gravel, sand, or soil. It’s built to handle rough, heavy loads and is shaped to help the material slide out quickly when it’s time to unload.

- Hydraulic Lift System: This system does the heavy lifting—literally. It uses pressurized fluid to push a metal cylinder, which raises the front of the dump bed. Once the bed tilts, gravity pulls the material down and out through the back. Without this system, you’d be stuck unloading by hand.

- PTO (Power Take-Off): The PTO connects the engine to the hydraulic system. When you flip it on, it sends power from the engine to the hydraulic cylinder so the bed can lift. It’s a small switch, but it’s one of the most important parts of the whole process.

- In-Cab Controls: These are the levers or switches you use to raise and lower the bed, and to turn the PTO on and off. They’re usually located on the side of the seat or dashboard, within easy reach of the driver. After a little practice, using them becomes part of your routine.

- Tires and Suspension: Since dump trucks carry heavy loads, they’re fitted with thick, durable tires and a strong suspension system. The suspension helps keep the truck stable, especially when you’re carrying full loads or driving over rough ground.

Once you understand these parts, it’s easier to spot problems, follow safety steps, and handle the truck with more confidence. Let’s take a closer look at what you should check before driving.

3. Types of Dump Trucks and Their Functions

Choosing the right dump truck makes a big difference. One crew I worked with used a standard dump truck on soft ground, thinking it would be fine. It wasn’t. The truck sank halfway through the job, and everything stopped. The right equipment could’ve saved them hours.

Each dump truck is built for a specific kind of work. Some are better for city streets. Others are made for rough terrain or fast unloading. Here’s a breakdown to help you decide which one fits your job.

Standard Rear Dump Truck

This is the most common type. It unloads by lifting the bed and dropping material straight out the back. It works well for short hauls on solid, level ground. You’ll see it often on small construction jobs or around neighborhoods.

If you’re hauling gravel or sand to a clear, flat area—this is a good choice.

Side Dump Truck

These trucks unload by tipping to the side, which makes them faster and more stable in some situations. They’re ideal for wide, open spaces like highways or large job sites. A crew I visited used side dumpers because they could unload and reset quickly without slowing traffic.

If you need speed and space, side dumps are worth looking at.

Bottom Dump (Belly Dump)

A bottom dump opens from underneath, letting the material fall out in a straight line as the truck moves. This makes it great for spreading gravel or road base evenly across long paths.

If your job needs smooth, even coverage while driving, this one’s made for it.

Articulated Dump Truck

These trucks are built with a joint in the middle that lets the front and back move separately. That gives better control on uneven, hilly, or muddy ground. They handle rough terrain where standard trucks get stuck.

If you’re hauling on slopes or soft ground, this truck gives you the flexibility to keep moving.

Off-Highway Dump Truck

These are the heavy haulers. You’ll find them on mining sites or big excavation projects. They aren’t made for regular roads—they’re built to carry massive loads across rough areas all day long.

If your job involves extreme hauling in off-road zones, this is the truck to consider.

4. Operator Training and Certification Requirements

Learning to drive a dump truck takes more than just climbing in and turning the key. You’ve got power under your feet, weight behind your back, and safety on the line. Before you can haul your first load, you need the right training—and in many cases, the right license too.

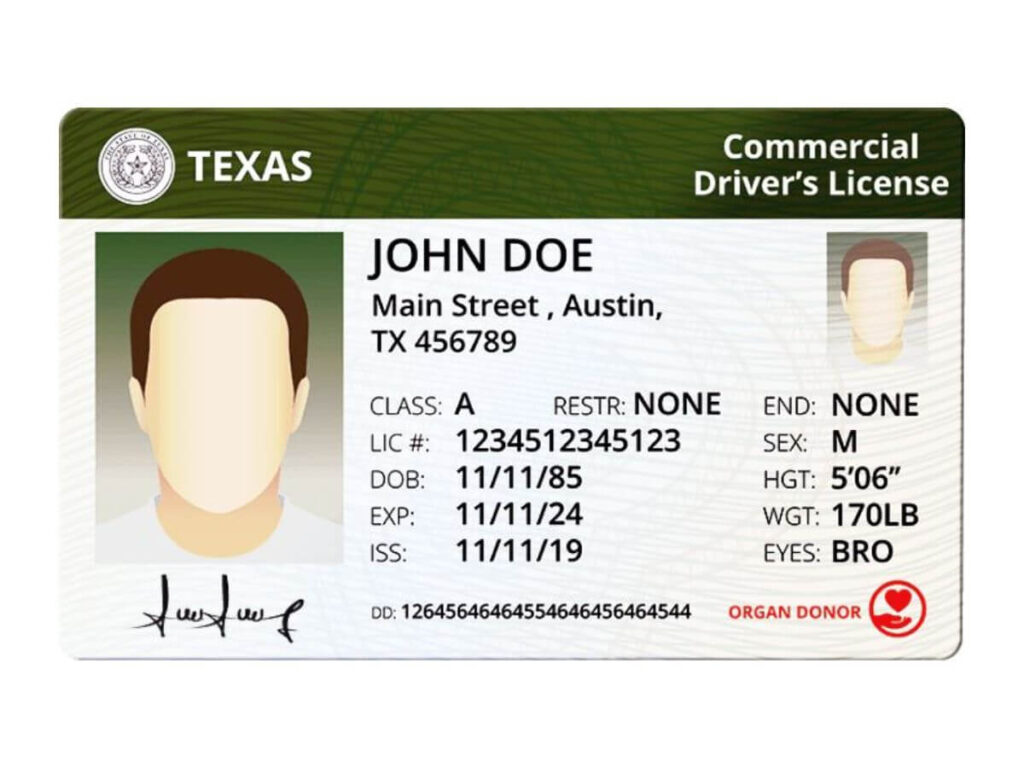

Do You Need a CDL?

In most cases, yes. If the dump truck has a gross vehicle weight rating (GVWR) of 26,001 pounds or more, you’ll need a CDL, or Commercial Driver’s License.

This license proves that you’ve been trained to handle heavy-duty vehicles. Some smaller trucks may not require one, but most full-size dump trucks will.

Check your local Department of Transportation (DOT) rules—they can vary by state or country. In the U.S., you’ll likely need a Class B CDL for a straight dump truck and a Class A CDL if you’re pulling a trailer with it.

What Skills Should You Have?

Before stepping into the driver’s seat, you’ll need to know more than just how to shift gears. You should know:

- How to load and unload safely

- How to drive with a full bed, especially on slopes or loose surfaces

- How to check brakes, tires, lights, and hydraulic systems before a shift

- How to back up and position the truck accurately

You’ll also need strong attention and quick thinking. Job sites can be loud, crowded, and unpredictable.

What About Safety Training?

Many employers offer or require safety training. These courses teach how to avoid rollovers, protect others around the truck, and respond to problems fast.

Some jobs may also require OSHA certification or similar industry-specific training.

Does Training Change by Region?

Yes. Some areas have extra rules or certifications depending on the job site. For example, working in mining or on federal roads may come with added training steps.

Before starting any job, always ask: Do I have the right license and training for this site and this truck?

When you’re confident in your training, you don’t just follow the rules—you protect yourself, your crew, and everyone around you.

5. Pre-Operation Inspection Checklist

Before you start up a dump truck, take a few minutes to walk around it. That quick check could save you from a breakdown—or an accident.

I once watched a driver skip this step. He pulled out with a slow leak in a hydraulic line. Halfway through the job, the bed wouldn’t lift. The delay cost his team half a day. A five-minute check could’ve avoided all of it.

Doing a pre-trip inspection isn’t just a box to check—it’s how you keep your truck, your load, and yourself safe.

Here’s what you should check before every job:

- Brakes: Tap the pedal. Listen to air leaks or strange sounds. Make sure the parking brake holds the truck still.

- Lights and Signals: Turn on your headlights, brake lights, and turn signals. If they don’t work, other drivers can’t see what you’re doing.

- Horn and Mirrors: Sound the horn once. Make sure it’s loud enough. Then adjust your mirrors so you can see clearly on both sides.

- Tires: Walk around the truck. Look for worn-out treads, low pressure, or cuts in the rubber. Don’t forget to check the spare.

- Hydraulic Lines and Cylinders: Look under the bed for leaks, bent parts, or cracked hoses. Any sign of damage here could stop the dump bed from working.

- Fluid Levels: Check oil, coolant, brake fluid, and hydraulic fluid. Top off anything that’s low.

- Load Limits: Know how much your truck can carry. Overloading it puts pressure on the brakes, tires, and frame—and it can be dangerous.

- Frame and Suspension: Look for rust, cracks, or broken parts. If anything looks loose, bent, or out of place, stop and report it.

- Cab Cleanliness and Visibility: Wipe off the windows and mirrors. Clear any trash or gear off the floor. If your view is blocked, your safety drops.

You don’t need fancy tools for this—just your eyes, ears, and a little time.

A good inspection is your first line of defense. Treat it like part of the job, and it’ll save you in the long run.

6. Step-by-Step Guide to Operating a Dump Truck

On a job site I visited, a driver dumped a load on uneven ground. The bed was halfway up when the truck leaned too far. He managed to stop it in time, but it could’ve gone bad fast. That moment showed me how important it is to follow the right steps every time.

Dump trucks are powerful machines, but small mistakes can lead to big problems. Here’s a simple guide to help you operate one safely and with confidence.

- Start-Up and Control Checks: Sit in the cab and start the engine. Let it run for a moment while you check the gauges. Test the brakes, horn, lights, and mirrors. Make sure the PTO switch is off before moving. Keep your windows clean and control within easy reach.

- Load the Material Evenly: A balanced load matters more than you think. If the material sits too far to one side or piles up too high, it can shift when you move or dump. Work with the loader to keep things level and steady.

- Drive With a Full Load: Hauling heavy material takes more control. Go slow, especially when turning or stopping. Keep both hands on the wheel and watch the road closely. Sudden movements can shift the load and throw off your balance.

- Pick a Safe Dumping Spot: Don’t dump on soft or sloped ground. Look for firm, level ground with enough room to reverse and exit. If you’re unsure about the surface, stop and take a closer look.

- Engage the PTO and Lift: Once you’re in position, turn on the PTO. Pull the control to raise the bed slowly. Keep an eye on the load through your mirrors. If it doesn’t flow out evenly or anything seems off, stop right away.

- Lower the Bed Safely: After dumping, lower the bed slowly and turn off the PTO. Make sure the bed is all the way down before moving. A half-raised bed can be dangerous on the road.

7. Safety Tips While Using a Dump Truck

When you’re behind the wheel of a dump truck, safety should be part of every move. Whether you’re dumping, driving, or loading, your choices affect not just you but everyone around the truck.

Follow these key tips to keep yourself and others safe in every job.

Don’t Dump on Soft or Sloped Ground

Check the ground before you raise the bed. Stick to firm, level areas where the truck stays steady during the lift. Soft soil or uneven spots can shift under your tires, which makes the truck less stable as the bed goes up.

Keep Others Clear of the Dump Area

No one should be near the back or sides of the truck while you unload. Gravel, dirt, or rock can fall fast and wide if the load shifts. Always keep the dumping zone clear and use cones or signs to mark the area if needed.

Use Wheel Chocks When Needed

Wheel chocks are small wedges you place behind the tires to help stop the truck from rolling. They’re important on slopes or uneven surfaces, especially when you’re parked with a full load. Adding that extra control helps you stay in place during loading or dumping.

Don’t Drive With the Bed Raised

Always bring the bed down before moving. A raised bed can hit overhead wires, signs, or throw the truck off balance when turning. Make it part of your routine to double-check the bed position before pulling away.

Use Safety Tools That Help You See

Backup alarms, mirrors, cameras, and spotters are all part of safe operation. At Rhinotrail, we know how important visibility is, which is why our trailers support clear lines of sight and use-friendly safety features. Alarms let others know you’re backing up, and cameras help you catch blind spots. When space is tight, a spotter on the ground can guide you in with confidence.

8. Routine Maintenance and After-Use Protocols

Running a dump truck isn’t just about hauling and dumping—it’s also about keeping the truck in good shape after the job is done. A well-maintained truck runs better, lasts longer, and keeps you safer on the road.

Here’s how you can build a solid routine after each use.

Clean the Cab and Do a Visual Check

- Remove trash and clear anything from the floor that could block your pedals

- Wipe down mirrors, windows, and controls for better visibility

- Walk around the truck and look for anything out of place—check for leaks, cracked lights, or low tires

Lubricate Moving Parts and Check Hydraulics

- Grease any moving parts like hinges, joints, and latch points

- Inspect the hydraulic lines for cracks, leaks, or loose fittings

- Check hydraulic fluid levels and top off if needed

- Watch for slow bed movement, which may mean a pressure issue

Clean the Dump Bed

- Shovel out leftover gravel, soil, or wet material

- Rinse the bed if needed to prevent buildup or rust

- Look for signs of wear, rust, or damage inside the bed

Schedule Regular Maintenance

- Set service dates for key systems like brakes, suspension, engine, and transmission

- Follow the manufacturer’s maintenance guide to stay on schedule

- Don’t skip inspections—catching small problems early saves time and money

Log Any Issues or Repairs

- Keep a notebook or digital log inside the cab

- Write down odd noises, warning lights, or anything that doesn’t feel right

- Report problems right away, so repairs can be made before your next shift

By making these steps part of your routine, you take better care of your truck and avoid surprise breakdowns. A well-maintained truck is safer, lasts longer, and keeps your jobs on track.

9. 5 Factors to Consider Before Using a Dump Truck

Before you bring a dump truck to your jobsite, it’s important to think through a few key details. Using the right truck for the right job saves you time, keeps your crew safe, and helps you avoid costly mistakes.

Here are the main things you should think about before getting started.

#1 Jobsite Conditions

- Look at the terrain. Is it flat, sloped, muddy, or rocky? Some trucks handle rough ground better than others.

- Check your space. Do you have room to turn, dump, and exit without backing into tight spots?

- Think about the material. Wet soil, gravel, or broken concrete all behave differently in the bed. Some stick, some slide—so your dumping area needs to match.

#2 Payload and Dump Capacity

- Payload means how much weight your truck can carry safely.

- Dump capacity is how much the bed holds by volume (like cubic yards).

- Know how much you plan to move and make sure the truck can handle it without overloading.

#3 Type of Dump Truck

- Choose based on the job.

- Rear dump trucks are good for short hauls on solid ground.

- Side dumps unload faster on wide, open sites.

- Belly dumps are best for spreading gravel or base material.

- Articulated trucks work better off-road or on soft ground.

#4 Buy or Rent?

- Ask yourself how often you’ll use it.

- Renting might be better for short-term jobs or seasonal use.

- Buying makes sense for long-term projects or regular hauling.

- Factor in storage, maintenance, and insurance when comparing costs.

#5 Driver Skill and Availability

- Do you have a trained driver with the right license?

- If not, you may need to hire one or allow time for proper training.

- A truck is only useful if someone can run it safely.

Thinking through these details before using a dump truck helps you stay on budget, stay safe, and get the job done right. The more you plan up front, the smoother things go on site.

Conclusion

You’ve got everything you need—truck types, inspection steps, loading tips, safety rules, and maintenance basics.

No more guessing. No more figuring it out alone.

What matters now is putting that knowledge to work.

Every safe haul begins with the right information—and now, you’ve got it.

If you’re serious about finding the right dump truck for your work, contact us today.