A few years ago, I got a call from someone facing a serious issue. They had ordered intermodal chassis that looked fine on paper—but the specs were wrong, and the quality didn’t hold up.

That mistake nearly cost them a major contract.

After helping them recover, I started paying close attention to which manufacturers were actually reliable.

Since then, I’ve worked with teams handling everything from bulk cargo to containers, learning firsthand who delivers and who falls short.

This list comes from that experience.

It includes 7 intermodal chassis manufacturers, with key facts like their location, company size, founding year, strengths, and known weaknesses.

By the end, you’ll have a practical way to choose the right supplier for your transport or cargo operations—without the guesswork.

Let’s get started!

Quick Comparison Chart

Before diving into each manufacturer in detail, here’s a quick side-by-side look at the basics—just to give you a feel for what sets each one apart.

| Manufacturer | Year Established | Headquarters | Specialty Products | Manufacturing Scale | Best For |

| CIE Manufacturing | 1980 | South Gate, California, USA | Intermodal chassis | Large-scale, USA-based | High-volume fleet buyers |

| Hyundai Translead | 1989 | San Diego, California, USA | Dry vans, refrigerated trailers, chassis | High-volume, Mexico-based | Regional carriers and large fleets |

| Rhinotrail | 2013 | Liangshan, Shandong, China | Semi-trailers, container chassis | Medium-scale, China-based | Buyers who need flexibility, speed, and hands-on service |

| Wabash National | 1985 | Lafayette, Indiana, USA | Dry vans, tankers, flatbeds | Large-scale, USA & Mexico | Long-haul logistics and trailer leasing |

| Pratt Industries (PIC) | 1973 | Niles, Michigan, USA | ISO container chassis | Mid-size, USA-based | Domestic container and port operations |

| Hercules Chassis | 1958 | Hillsborough, New Jersey, USA | Custom container chassis | Small to mid-size, USA-based | Custom builds and specialized use |

| Stoughton Trailers | 1961 | Stoughton, Wisconsin, USA | Intermodal chassis, dry vans, refrigerated trailers | Multi-plant USA production | Buyers needing U.S.-built trailers with consistent quality |

Now let’s take a closer look at each manufacturer, one by one.

1. CIE Manufacturing

I first came across a CIE chassis while helping a client compare options for a port fleet upgrade. One unit stood out—tight welds, clean layout, no shortcuts. That moment pushed me to look deeper into who built it.

CIE Manufacturing was established in 2015 and is headquartered in South Gate, California. Backed by CIMC, a global leader in logistics equipment, CIE operates several facilities across the U.S. With around 250 employees, the company focuses on building high-volume chassis designed for the American market.

Product Range

- Intermodal chassis for 20’, 40’, and 45’ containers

- Lightweight gooseneck chassis

- Tandem and tridem axle options

- CityCombo WS 20/40 (top-seller)

- USMCA-compliant designs

- Heavy-duty port-use models

Manufacturing Capabilities

- High-capacity output, tens of thousands per year

- U.S.-based production for quicker turnaround

- Container-specific chassis builds

- Advanced welding and surface treatment processes

- Limited customization for large fleets

- Gradual shift from Chinese to U.S. components

Customer Support & After-Sales Service

- Phone, email, and web-based contact

- Account managers for commercial clients

- Quick response times reported by users

- Maintenance guides and usage tips available

- Help with troubleshooting and spare parts support

Final Verdict

CIE is a smart pick for buyers who need dependable, high-volume chassis that perform under pressure. Their focus on U.S.-based production and proven track record makes them a solid choice for standard container transport. However, if your operation requires more flexibility or specialized builds, you may want to explore manufacturers that offer broader customization.

2. Hyundai Translead

I inspected a Hyundai Translead chassis, I was helping a customer decide between a few major brands. We walked the yard together. His first comment? “This one looks cleaner and tougher.” He was right. The frame, the build, the finish—it all felt well thought out. That moment stuck with me.

Hyundai Translead was established in 1989 and is headquartered in San Diego, California. They employ over 1,000 people and operate large-scale manufacturing facilities in Tijuana, Mexico. As a part of Hyundai Motor Company, they bring both global backing and decades of trailer manufacturing experience. They were also the first North American trailer manufacturer to earn ISO 9001 certification, proving their long-term commitment to quality.

Product Range

- Chassis for 20’, 40’, 45’, 48’, and 53’ containers

- Extendable and fixed chassis

- Gooseneck container chassis

- Dry van trailers (Original®, HY-Cube®, Composite®)

- Refrigerated trailers (ThermoTech®)

- Flatbeds and converter dollies

Manufacturing Capabilities

- Produces thousands of trailers and chassis each month

- In-house production across several facilities in Mexico

- Offers custom specs for large orders

- Uses automated welding and coating systems

- Focused on container and trailer builds only

- ISO 9001 certified for manufacturing quality

Customer Support & After-Sales Service

- Contact available through phone, email, and online portal

- Regional sales managers provide dedicated support

- Fast service response and clear claim processes

- Offers a full warranty program

- Guides and manuals available for training and maintenance

Final Verdict

Hyundai Translead is a dependable choice for fleets looking for high-volume chassis with consistent build quality and strong after-sales support. Their global backing and ISO-certified facilities add confidence for buyers focused on reliability. However, smaller companies looking for niche or highly flexible chassis options may find fewer options here.

3. Rhinotrail

Rhinotrail was founded in 2013 and is based in Liangshan, Shandong, China. With over 12 years in the industry, they’ve grown into a large-scale manufacturer supplying semi-trailers across Asia, Africa, and South America. Their team numbers in the hundreds, and their production facilities run year-round to meet global demand.

When you walk up to a Rhinotrail trailer, you feel the weight in the steel and see the precision in every weld. Their builds don’t just look clean—they’re made to haul, handle, and last.

Product Range

- Intermodal chassis for container transport

- Flatbed trailers for large or oversized cargo

- Low-bed trailers for heavy machinery

- Dump trailers for mining and bulk loads

- Skeletal trailers for port and terminal work

- Fence, warehouse, and animal transport trailers

Manufacturing Capabilities

- High-volume production with small or bulk order flexibility

- Full focus on trailer and chassis manufacturing

- In-house cutting, welding, blasting, and painting

- Customized specs based on weight, load type, or road conditions

- Modern CNC machines and robotic welding lines

- International delivery with pre-shipment inspections and documents

Customer Support & After-Sales Service

- Quick replies through phone, email, or WhatsApp

- English-speaking sales and technical support

- Design previews and live production updates

- Help with shipping, setup, and maintenance

- Spare parts and drawings sent fast when needed

- Built-in support for long-distance buyers

Final Verdict

Rhinotrail blends durability with thoughtful service. Their trailers feel like they’re made for real roads—heavy steel, clean finishes, and no wasted space. If you’re looking for a build that works hard and a team that moves fast, Rhinotrail brings both to the table.

4. Wabash National Corporation

If you’ve been in this industry long enough, you’ve probably seen a Wabash trailer on the road—or maybe you’ve used one yourself. I once helped a client update their fleet and Wabash kept coming up in the conversation. Their trailers weren’t just well-built—they were reliable, easier to maintain, and always showed up ready for work.

Wabash was founded in 1985 and is based in Lafayette, Indiana. With over 6,000 employees and multiple U.S. and Mexico-based factories, they produce trailers, chassis, tankers, and composite materials for commercial transport. Their scale is big—but their attention to detail is what stands out.

Product Range

- Intermodal chassis and container equipment

- Dry vans (for non-refrigerated cargo)

- Refrigerated trailers (ThermoTech®)

- Flatbeds and drop decks

- Tank trailers (liquids, food-grade, chemicals)

- Composite body panels (DuraPlate® technology)

Manufacturing Capabilities

- Large-scale output: tens of thousands of trailers per year

- Facilities in Indiana, Kentucky, and Mexico

- Offers custom builds for commercial fleets

- Develops proprietary materials like DuraPlate®

- Uses automated welding, forming, and coating systems

- Focus on innovation and sustainable materials

Customer Support & After-Sales Service

- Support through phone, email, and dealer network

- Dedicated reps for major clients and fleets

- Warranty programs and claim support

- Parts and service available nationwide

- Maintenance guides and resources for fleet teams

Final Verdict

Wabash National is a strong pick if you’re looking for well-engineered trailers built at scale. Their focus on quality and innovation makes them a reliable partner for long-term fleet needs. However, if you need highly specialized or low-volume builds, a smaller manufacturer might offer more flexibility.

5. Pratt Industries (PIC)

If you’ve ever tried finding a U.S.-based chassis builder with real experience in ISO container transport, you’ve likely come across Pratt. I remember helping a regional carrier who needed a 40′ gooseneck chassis fast—and Pratt delivered. The units came clean, prepped, and ready to hit the yard with no fuss.

Pratt Industries, also known as Pratt Intermodal Chassis (PIC), was founded in 1973 and is based in Niles, Michigan. With decades of experience and a focused team, they build and supply intermodal chassis across North America.

Product Range

- 20’, 40’, and 45’ container chassis

- Gooseneck and straight-frame chassis

- Tandem and tridem axle configurations

- Tank container chassis

- Custom builds for fleets and leasing companies

- DOT-compliant and ISO-standard options

Manufacturing Capabilities

- Large-scale U.S. production from Michigan facility

- Focus on steel intermodal chassis

- Handles small to large batch orders

- In-house design, welding, and assembly

- Custom engineering for weight and container size

- Standard and premium models available

Customer Support & After-Sales Service

- Phone and email support through U.S. team

- Clear quoting process and fast lead time updates

- Optional parts and service packages

- Works with leasing firms and direct buyers

- Support staff for technical issues and warranty

- Custom paint, branding, and spec options available

Final Verdict

Pratt is a dependable choice if you need U.S.-built chassis that are tough, simple, and backed by experience. They’re especially strong for container fleets and companies with recurring orders. However, if you’re looking for advanced automation or broader trailer types, other manufacturers may offer more variety.

6. Hercules Chassis

If you’ve ever stood next to a Hercules chassis, you know what solid feels like. The first time I saw one up close, it had just rolled off a port delivery. The paint was fresh, the welds were clean, and the frame looked like it could take a hit and keep rolling. The driver leaned over and said, “This thing’s built like a tank.”

Hercules Chassis was founded in 1958 and operates out of Hillsborough, New Jersey. With over 60 years in the game, they’ve become a go-to for custom intermodal chassis in the U.S. Everything is designed and built stateside, so if you care about hands-on service and quick responses, they’ve got you covered.

Product Range

- 20’, 40’, and 45’ container chassis

- Combo chassis that fit multiple container sizes

- Tank container chassis for liquid cargo

- Extendable and gooseneck designs

- Custom chassis built to your exact spec

- Heavy-duty builds for port and yard operations

Manufacturing Capabilities

- U.S.-based production with short lead times

- In-house welding, painting, and fabrication

- Custom designs for weight, axle spacing, or cargo type

- Powder-coated finishes for weather resistance

- Builds range from single orders to full fleet runs

- Uses heavy-gauge steel and premium components

Customer Support & After-Sales Service

- U.S. team available by phone or email

- Personal service from sales through delivery

- Fast responses and updates during production

- Optional support for maintenance and repairs

- Can help with DOT requirements and documentation

- Clear communication from a tight-knit team

Final Verdict

Hercules is a strong fit if you want a chassis that feels solid under load and holds up to daily use. Their builds are made to be seen, touched, and trusted. However, if you’re looking for mass production or international scale, larger global players may offer more volume-based options.

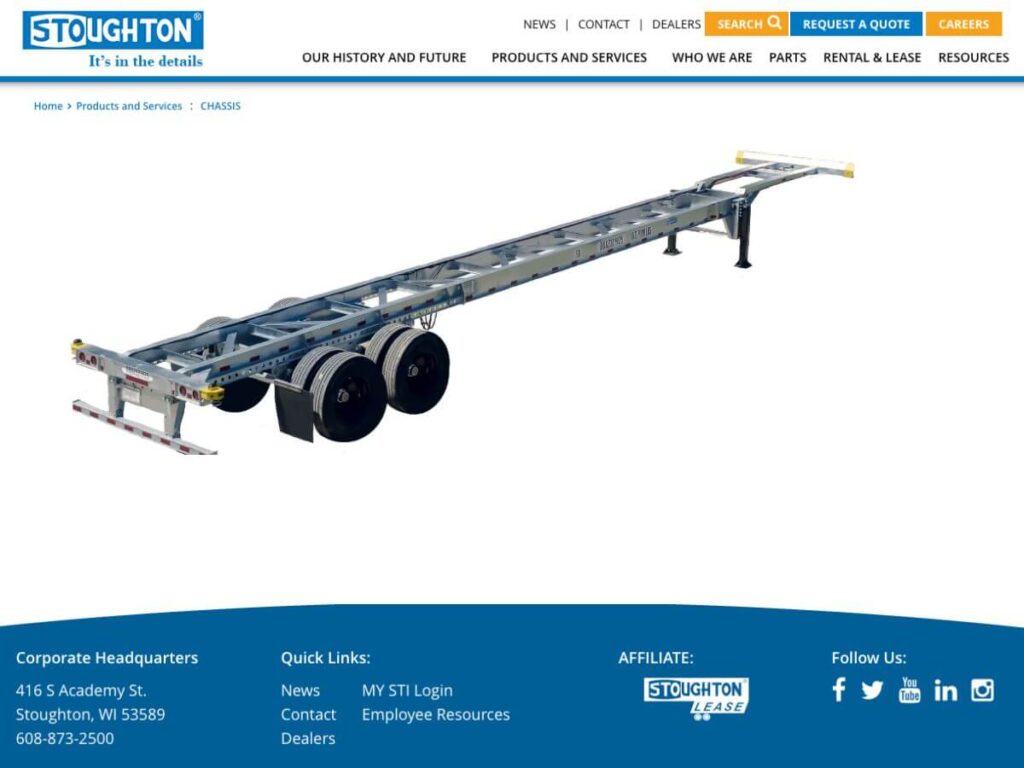

7. Stoughton Trailers

If you want a chassis that feels solid the moment it rolls into your yard, Stoughton is worth a close look. I once worked with a freight company that swapped out older units for Stoughton chassis. The welds were cleaner. The paint held better. And the drivers noticed the smoother pulls right away.

Founded in 1961 and based in Stoughton, Wisconsin, the company has grown to include several facilities across the U.S. They build trailers and chassis for container transport, over-the-road freight, and agriculture—built tough, built local, and built with pride.

Product Range

- Intermodal chassis (20′, 40′, 45′, and combo frames)

- Dry van trailers

- Grain trailers for ag hauling

- Refrigerated trailers for cold-chain shipping

- Custom chassis for specialized loads

Manufacturing Capabilities

- U.S.-based plants in Wisconsin and Texas

- ISO 9001:2015 certified for quality

- In-house chassis production and assembly

- Custom chassis specs available for bulk orders

- Galvanized and painted chassis finish options

- Advanced robotics and automated forming equipment

Customer Support & After-Sales Service

- Phone and email support available through U.S. team

- Backed by a national dealer network

- Warranty support on chassis and trailers

- Parts readily available for fast replacement

- Personalized help for orders and maintenance needs

Final Verdict

Stoughton is a smart pick if you’re looking for a chassis built in the U.S. with attention to detail and solid support behind it. Their builds hold up under pressure and offer real long-term value. However, if you need global delivery or offshore options, other manufacturers may be a better fit.

Conclusion

I’ve watched businesses lose time and money over the wrong chassis. I’ve also seen how fast things turn around when they choose right.

This article gave you the knowledge. 7 trusted manufacturers. Real details. Real differences.

Now it’s up to you.

You’re not stuck. You’re just one step away from a better solution.

Have questions or need help deciding?

Contact us today to get started on your next trailer order.