I used to spend hours reading spec sheets and reviews. Even then, I still ended up with trailers that didn’t hold up. One even cracked under load.

That frustration led me down a path of talking to real people—shop owners, operators, and mechanics. That’s how I built my list.

I’ve worked with trailers for years. I’ve seen how the right one makes your life easier—and how the wrong one drains time and money.

This article brings together the 7 best trailer manufacturers in the USA. Not based on hype, but on real-world results. You’ll get straight answers. No sales talk. Just what each manufacturer does well—and who they serve best.

By the end, you’ll be better equipped to choose one that fits your work and budget.

So let’s start!

Comparison Table

Before we delve into an in-depth analysis of each manufacturer, here’s a concise comparison to provide you with a snapshot of their key attributes:

| Manufacturer | Established | Location | Notable Products | Strengths |

| Hyundai Translead | 1989 | California, USA | Dry Van Trailers, Refrigerated Trailers, Flatbeds, Chassis, Dollies | Advanced manufacturing facilities, innovative technologies |

| Wabash National Corporation | 1985 | Indiana, USA | Dry Freight and Refrigerated Trailers, Platform Trailers, Tank Trailers, Truck Bodies | Advanced materials like EcoNex and DuraPlate® |

| Great Dane | 1900 | Georgia, USA | Dry Van Trailers, Refrigerated Trailers, Flatbed Trailers | Century-long experience, pioneering refrigerated trailers |

| Utility Trailer Manufacturing Company | 1914 | California, USA | Refrigerated Trailers, Dry Freight Vans, Flatbed Trailers, Curtainsided Trailers | Largest producer of refrigerated vans in the U.S. |

| Stoughton Trailers | 1961 | Wisconsin, USA | Dry Van Trailers, Refrigerated Trailers, Grain Trailers, Chassis | Durable grain trailers, multiple production facilities |

| Vanguard National Trailer Corp | 2003 | Indiana, USA | Dry Freight Van Trailers, Refrigerated Trailers, Flatbed Trailers, Converter Dollies, Container Chassis | Corrosion-resistant materials, thermal efficiency |

| MAC Trailer Manufacturing | 1994 | Ohio, USA | Dump Trailers, Pneumatic Tank Trailers, Flatbed and Drop Deck Trailers, Transfer Trailers | Specialized, customizable trailers |

Now, let’s explore each manufacturer in detail to understand their offerings and how they align with your specific needs

1. Hyundai Translead

Established Date: 1989

Location: California, USA

Choosing the right trailer manufacturer can be challenging. I’ve faced this challenge myself, wading through options to find a reliable partner. One name that consistently stood out to me was Hyundai Translead.

As a subsidiary of Hyundai Motor Company Korea, they specialize in producing transportation equipment like dry and refrigerated van trailers and dollies. Notably, they were the first major North American trailer manufacturer to receive ISO 9001 Certification in 1996, reflecting their commitment to quality management systems.

Product Range

Hyundai Translead offers a variety of products to meet diverse transportation needs:

- Dry Van Trailers: Models like the Original®, HY-Cube®, Composite®, and Composite XT® are designed for durability and efficiency.

- Refrigerated Trailers: The ThermoTech® line ensures temperature-sensitive cargo remains in optimal condition.

- Flatbeds: Versatile solutions for transporting large or irregularly shaped loads.

- Chassis and Dollies: Designed to support various container sizes and weights.

Manufacturing Capabilities

Hyundai Translead’s manufacturing strengths include:

- State-of-the-Art Facilities: In 2006, they expanded with the “H-Line,” increasing production by 30%. In 2016, the “I-Line” facility further boosted capacity by 50%.

- Innovation Lab (iLab): Established in 2022, this 174,000-square-foot facility focuses on product development and testing, featuring equipment like a full trailer road simulator and automated floor testing systems.

- Advanced Assembly Processes: Utilizing automatic floor and semi-automatic wall assembly techniques to enhance build quality.

Technological Advancements

Hyundai Translead integrates innovative technologies into their products:

- HT LinkVue®: A 360-degree trailer camera system that enhances driver visibility, reduces blind spots, and aids in tight dock maneuvers.

- HT LinkSense: A sensor-telematics solution that collects and uploads data, providing insights into trailer status and activity.

- Anza Truck Body: A medium-duty truck body that can be shipped as a kit, reducing shipping costs and allowing for easy on-site assembly, redefining the truck body supply chain.

Key Takeaway

Selecting the right trailer manufacturer is vital for your hauling operations. Based on customer feedback and the company’s established presence in the industry, Hyundai Translead emerges as a dependable choice for those seeking durable and well-engineered trailers.

However, some customers have reported challenges with communication and responsiveness. It’s advisable to maintain direct contact with Hyundai Translead or their authorized dealers to obtain accurate information and ensure your specific needs are addressed promptly.

2. Wabash National Corporation

Established Date: 1985

Location: Indiana, USA

Wabash National Corporation has grown into a leading manufacturer of engineered solutions for the transportation, logistics, and distribution industries. Their focus on developing advanced materials like EcoNex and DuraPlate® demonstrates a forward-thinking approach that can translate into tangible benefits for your fleet.

Product Range

Wabash National offers a comprehensive suite of products tailored to meet diverse transportation requirements:

- Dry Freight and Refrigerated Trailers: Designed for durability and efficiency, these trailers cater to standard cargo and temperature-sensitive goods alike.

- Platform Trailers: Ideal for transporting oversized or uniquely shaped loads that require open deck space.

- Tank Trailers and Truck-Mounted Tanks: Engineered for the safe transport of liquids and gases, adhering to stringent safety standards.

- Truck Bodies: Both dry and refrigerated options are available, providing flexibility for various delivery needs.

- Structural Composite Panels: Utilized in the construction of lightweight yet robust trailers, enhancing fuel efficiency without compromising strength.

- Laminated Hardwood Oak Flooring: Supplies a sturdy foundation for trailers, ensuring longevity and resilience under heavy loads.

Manufacturing Capabilities

Wabash National’s manufacturing prowess is evident through:

- Advanced Production Facilities: Strategically located plants equipped with cutting-edge technology to streamline production and maintain high-quality standards.

- Innovative Assembly Techniques: Implementation of automated systems to enhance precision and reduce production times.

- Quality Control Measures: Rigorous testing protocols to ensure each product meets industry and customer specifications.

Technological Advancements

Innovation is at the heart of Wabash National’s operations:

- EcoNex Technology: A proprietary composite material designed to improve thermal efficiency in refrigerated transportation, reducing energy consumption.

- DuraPlate® Composite Panels: Offer enhanced durability and resistance to damage, extending the lifespan of trailers.

- Advanced Telematics Integration: Enables real-time tracking and monitoring of trailer conditions, enhancing fleet management capabilities.

Key Takeaway

Wabash National is best for businesses seeking a diverse range of trailers and innovative transportation solutions. Their commitment to advanced materials and technology offers potential benefits for various hauling needs.

However, it’s worth noting that some customers have expressed concerns regarding communication and customer service responsiveness. To navigate this, I recommend establishing clear lines of communication from the outset and maintaining regular contact throughout your engagement.

3. Great Dane

Established Date: 1900

Location: Georgia, USA

I remember the first time I came across Hyundai Translead. A fellow hauler mentioned how their dry van had withstood years of rigorous use without significant wear. Intrigued by such durability, I decided to explore what made this manufacturer stand out in the competitive trailer market.

Great Dane has evolved into a leading manufacturer of transportation solutions. With over a century of experience, they’ve built a reputation for producing high-quality dry vans, refrigerated trailers, and flatbed trailers. They operates multiple manufacturing plants across the United States, ensuring widespread availability and support for their products.

Product Range

Great Dane offers a diverse lineup of trailers to meet various transportation needs:

- Dry Van Trailers: The Champion series provides customizable options, including sheet-and-post and composite models, designed for durability and efficiency.

- Refrigerated Trailers: The Everest series is engineered for temperature-sensitive cargo, featuring advanced insulation and cooling technologies to maintain optimal conditions.

- Flatbed Trailers: The Freedom line includes all-steel, steel-aluminum combo, and all-aluminum models, offering versatility for transporting large or irregular loads.

Manufacturing Capabilities

Great Dane’s manufacturing strengths include:

- Extensive Production Facilities: With multiple plants nationwide, they ensure efficient production and timely delivery of trailers.

- Advanced Engineering: Utilizing computer-aided design (CAD) and finite element analysis (FEA) to enhance trailer strength and reduce weight.

- Quality Assurance: Comprehensive testing protocols, including road simulation equipment, to verify durability and performance.

Technological Advancements

Great Dane integrates innovative technologies into their products:

- Pioneering Refrigerated Trailers: Introduced the first refrigerated aluminum trailers in 1947, revolutionizing the transport of perishable goods.

- Advanced Telematics: Incorporating systems that provide real-time data on trailer location and condition, improving fleet management.

Key Takeaway

Great Dane is best for businesses seeking a blend of historical reliability and modern innovation in their trailers. Their extensive experience and commitment to quality make them a dependable choice for various hauling needs.

However, some users have noted that the initial investment for Great Dane trailers can be higher compared to other suppliers. It’s important to assess your budget and long-term operational goals when considering Great Dane as your trailer provider.

4. Utility Trailer Manufacturing Company

Established Date: 1914

Location: California, USA

Utility Trailer Manufacturing Company is America’s oldest privately owned, family-operated trailer manufacturer. They specialize in designing and producing dry freight vans, flatbeds, refrigerated vans, and Tautliner® curtainsided trailers. Notably, Utility is the largest producer of refrigerated vans and ranks as the third-largest trailer manufacturer in the United States.

Product Range

Utility offers a diverse lineup of trailers tailored to various transportation needs:

- Refrigerated Trailers: Known for their 3000R® model, these trailers are designed to maintain precise temperature control, ensuring the safe transport of perishable goods.

- Dry Freight Vans: The 4000D-X Composite® series provides durability and efficiency for transporting non-perishable items.

- Flatbed Trailers: Models like the 4000AE® offer a blend of steel and aluminum, balancing strength with weight savings.

- Curtainsided Trailers: The Tautliner® combines the flexibility of a flatbed with the protection of an enclosed trailer, suitable for various cargo types.

Manufacturing Capabilities

Utility’s manufacturing strengths include:

- Multiple Production Facilities: With six plants across North America, including locations in Virginia, Utah, Arkansas, Alabama, and Mexico, they ensure widespread production and distribution.

- Advanced Engineering: Utilization of computer-aided design (CAD) and finite element analysis (FEA) to enhance trailer strength while reducing weight.

- Quality Control: Rigorous testing protocols, including on-site test tracks, to validate the durability and performance of their trailers.

Technological Advancements

Utility integrates innovative technologies into their products:

- Aero Technologies: Development of aerodynamic devices, such as the Utility Aerodynamic Tail, to improve fuel efficiency and reduce drag.

- Enhanced Insulation: Incorporation of advanced insulation materials in refrigerated trailers to maintain consistent temperatures and improve energy efficiency.

- Lightweight Materials: Use of high-strength, lightweight materials to increase payload capacity without compromising structural integrity.

Key Takeaway

Utility Trailer Manufacturing Company is best for businesses prioritizing durability and innovation in their trailer investments. Their century-long presence in the industry and focus on technological advancements make them a reliable choice for various hauling needs.

However, some customers have reported challenges with customer service responsiveness. For instance, reviews on Birdeye indicate mixed experiences, with some customers praising the quality of trailers but expressing dissatisfaction with communication and support. In my experience, while product quality met expectations, timely responses from customer service were occasionally lacking.

5. Stoughton Trailers

Established Date: 1961

Location: Wisconsin, USA

When I first started hauling agricultural products, I quickly realized the importance of having a reliable grain trailer. A fellow hauler recommended Stoughton Trailers, praising their durability and design tailored for grain transport. Intrigued, I decided to explore what Stoughton had to offer.

Over the decades, it has grown into one of North America’s leading manufacturers of conventional and intermodal transportation equipment. With additional facilities in Evansville and Brodhead, Wisconsin, as well as Waco, Texas, Stoughton remains committed to producing high-quality trailers for various industries.

Product Range

Stoughton offers a diverse lineup of trailers to meet different transportation needs:

- Dry Van Trailers: Designed for general freight, these trailers emphasize durability and efficiency.

- Refrigerated Trailers: Engineered to maintain precise temperature control for perishable goods.

- Grain Trailers: Specifically crafted for the agricultural sector, facilitating the transport of bulk grains.

- Chassis: Intermodal container chassis designed for transporting shipping containers.

Manufacturing Capabilities

Stoughton’s manufacturing strengths include:

- Multiple Production Facilities: With plants in Wisconsin and Texas, they ensure efficient production and distribution across North America.

- Advanced Engineering: Utilization of modern design techniques to enhance trailer strength while optimizing weight.

- Quality Control: Rigorous testing protocols to ensure each trailer meets high durability and performance standards.

Technological Advancements

Stoughton integrates innovative technologies into their products:

- Enhanced Aerodynamics: Design features aimed at reducing drag and improving fuel efficiency.

- Lightweight Materials: Incorporation of high-strength, lightweight materials to increase payload capacity without compromising structural integrity.

- Advanced Insulation: In refrigerated trailers, they use state-of-the-art insulation materials to maintain consistent temperatures and improve energy efficiency.

Key Takeaway

Stoughton Trailers is best for businesses seeking a blend of traditional craftsmanship and modern innovation in their trailers. Their commitment to quality and diverse product range make them a reliable choice for various hauling needs.

However, in my experience, while the grain trailer I purchased was exceptionally durable and met my general hauling requirements, I found limited options for tailoring specific features to my unique needs. It’s advisable to assess whether Stoughton’s available configurations align with your specific operational requirements before making a decision.

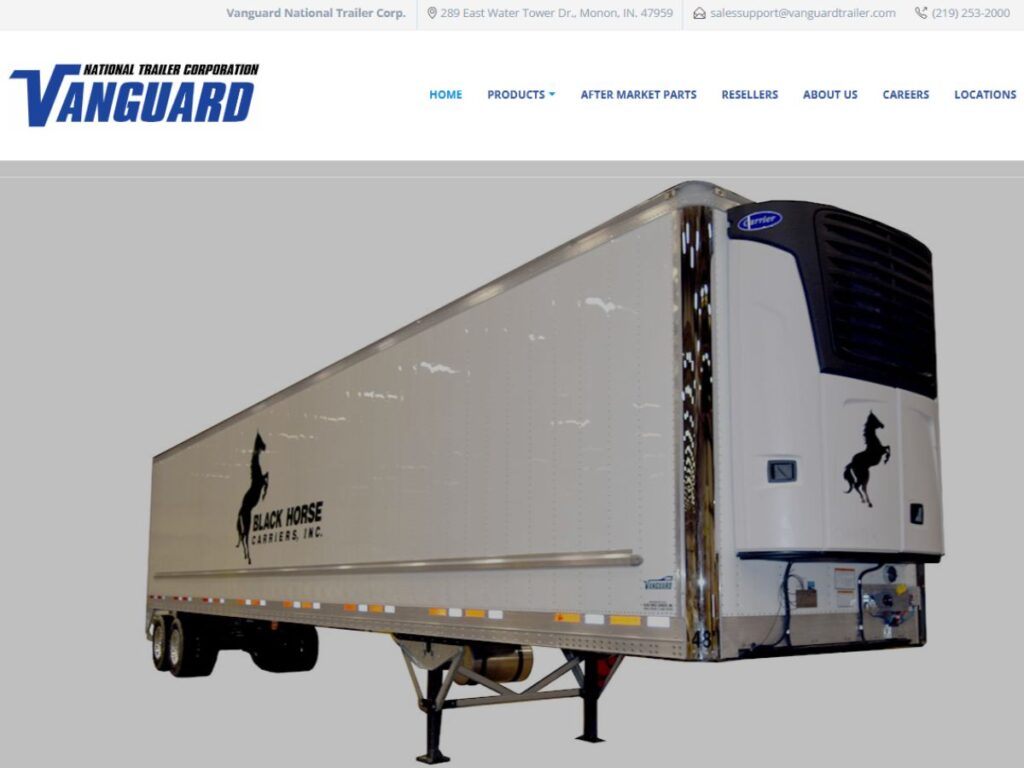

6. Vanguard National Trailer Corp

Established Date: 2003

Location: Indiana, USA

Vanguard National Trailer Corp. has rapidly ascended as a prominent manufacturer of dry freight and refrigerated semi-trailers in North America. As a subsidiary of the CIMC Vehicle Group, Vanguard benefits from a global network, enhancing its manufacturing capabilities and industry presence. The company’s dedication to quality and innovation is evident in its diverse product lineup tailored to meet the evolving demands of the transportation sector.

Product Range

Vanguard offers a comprehensive array of trailers designed for various transportation needs:

- Dry Freight Van Trailers:

- VIP 4000: A sheet and post model featuring a 100-inch interior width and 14-gauge logistics posts on 16-inch centers.

- MaxCube: Boasts a 101-inch anti-snag snap-in interior liner with recessed impact-resistant plastic between posts, eliminating fasteners.

- VXP: Features snag-free composite plate panels with galvanized logistics posts and an interior width of 101.25 inches.

- Refrigerated Trailers: Engineered for superior thermal efficiency, these trailers have been tested to be 12% more thermally efficient than others, featuring smooth, flat construction with foamed panels.

- Flatbed Trailers: Designed for versatility, accommodating various load types with an emphasis on strength and longevity.

- Converter Dollies: Facilitate the connection of multiple trailers, enhancing transport flexibility.

- Container Chassis: Support intermodal transportation by providing a reliable base for shipping containers.

Manufacturing Capabilities

Vanguard’s manufacturing strengths include:

- State-of-the-Art Facilities: Operations in Monon, Indiana, and Trenton, Georgia, equipped with advanced machinery to ensure precision and efficiency.

- Corrosion-Resistant Materials: Utilization of galvanized components and advanced coatings to enhance trailer longevity.

- Quality Assurance: Rigorous testing protocols to ensure each trailer meets stringent durability and performance standards.

Technological Advancements

Vanguard integrates innovative technologies into their products:

- Aerodynamic Designs: Incorporation of features that reduce drag, thereby improving fuel efficiency.

- Enhanced Safety Components: Standard inclusion of advanced safety features aimed at protecting both cargo and operators.

- Thermal Efficiency: Refrigerated trailers designed with foamed panels for superior temperature control, ensuring the integrity of perishable goods.

Key Takeaway

Vanguard National Trailer Corp. is best suited for businesses seeking trailers that offer a balance between durability and cost-effectiveness. Their focus on corrosion resistance and structural integrity makes them a reliable choice for various hauling needs.

However, Vanguard’s trailers may not always align with specific regional standards, which could pose challenges for businesses operating across different areas. I encountered some compliance issues when moving across state lines. It’s advisable to thoroughly research and ensure that any trailer you consider meets the regulatory requirements of all the regions in which you plan to operate.

7. MAC Trailer Manufacturing

Established Date: 1994

Location: Ohio, USA

MAC Trailer Manufacturing has grown into one of the nation’s foremost manufacturers of specialized trailers. They focus on producing a variety of trailers designed to meet the specific needs of industries such as construction, agriculture, and waste management. Their commitment to innovation and quality has earned them a solid reputation in the industry.

Product Range

MAC Trailer offers a diverse lineup of trailers to cater to various hauling needs:

- Dump Trailers: Available in both steel and aluminum, these trailers are designed for transporting bulk materials like sand, gravel, and demolition debris.

- Pneumatic Tank Trailers: Engineered for hauling dry bulk commodities such as cement, sand, and flour, ensuring product integrity during transport.

- Flatbed and Drop Deck Trailers: Ideal for transporting construction materials, machinery, and other oversized loads.

- Transfer Trailers: Designed for efficient waste transfer operations, enhancing payload capacity and operational efficiency.

Manufacturing Capabilities

MAC Trailer’s manufacturing strengths include:

- Advanced Fabrication Techniques: Utilizing cutting-edge welding and assembly processes to ensure structural integrity and longevity.

- Customization: Offering tailored solutions to meet specific customer requirements, reflecting their understanding of diverse industry needs.

- Quality Assurance: Implementing rigorous testing protocols to maintain high standards across all products.

Technological Advancements

MAC Trailer integrates innovative technologies into their products:

- Lightweight Materials: Incorporating aluminum and high-strength steel to reduce trailer weight, thereby increasing payload capacity and improving fuel efficiency.

- Enhanced Safety Features: Implementing advanced braking systems and lighting configurations to enhance on-road safety.

- Corrosion Resistance: Applying specialized coatings and using corrosion-resistant materials to extend the lifespan of their trailers.

Key Takeaway

MAC Trailer Manufacturing is best suited for businesses requiring specialized trailers that combine durability with innovative design. Their focus on customization and quality makes them a reliable choice for industries with unique hauling needs.

However, while the Great Dane trailer performed exceptionally on the road, coordinating timely maintenance services required proactive communication. One users have reported challenges with after-sales support, including delays in obtaining parts and service.

Can’t Find The Right Supplier in USA?

Is your search for the ideal trailer supplier in the USA hitting a dead end? The process can be daunting, especially when local options don’t quite match your expectations.

Have you thought about looking beyond the domestic market? Sometimes, the best solutions come from unexpected places.

At Rhinotrail, we pride ourselves on delivering top-notch trailers from China. If you’re open to exploring alternatives, we’d be delighted to discuss how our products can meet your requirements.

Here’s the reason why we are worth considering:

- Broader Selection: Access to a wider range of products tailored to various industries.

- Cost Savings: Potential for more affordable pricing due to different manufacturing economies.

- Customization: Flexibility to customize products to your specific needs.

Ready to explore the best? Contact us today for more information!

Conclusion

We’ve walked through 7 trailer manufacturers that dominate the U.S. market. You’ve seen their story, their strengths, and where they fall short.

Now it’s your chance to act.

You can stick with what’s familiar—or look outside the borders.

Rhinotrail might be your next best step. We’re not in the U.S., but we serve customers who couldn’t find their match locally.

Contact us today! We’re ready to help you find the trailer that works, not just looks good on paper!