At my first site job, I kept hearing “get the tractor ready.” I stared at a trailer for five minutes, wondering how to start it.

That moment stuck with me. Now, years later, I write for folks like you—those who want straight answers without the guesswork.

I’ve worked alongside drivers, loaders, and dispatchers, and I’ve asked all the same questions you might have.

So if you’re wondering what separates a tractor from a semi-trailer, you’re in the right place. I’m breaking it down in simple terms. No fluff. Just what you need.

And when you’re done reading, you’ll finally have the right tool in your head—knowing what’s what, and how they work together.

Let’s start!

1. What is a Tractor?

A tractor is the front part of a semi-truck. It’s the part with the engine, the driver’s cab, and the steering wheels. Its main job? To pull a trailer.

You might hear it called a truck tractor, prime mover, or just tractor unit—all these names refer to the same thing. It’s designed to connect to different types of trailers and pull heavy loads over long distances.

Tractors don’t carry cargo on their own. They’re made to haul trailers loaded with everything from building materials to groceries. That’s what makes them so important in transport work.

Think of the tractor as the muscle of the operation. Without it, the trailer goes nowhere.

Ever mix up the terms and call the whole thing a “semi-truck”? You’re not alone. But now you’ll know that the tractor is just the front half—the part that powers the whole trip.

Let’s break down its main features next.

Features

Here’s what sets a tractor apart:

- Engine and Drivetrain: This is the power source. It moves the entire unit, even when the trailer is loaded to the max.

- Fifth-Wheel Coupling: This large metal plate connects the tractor to the trailer. It lets the trailer pivot as you turn.

- Axle Configurations: These tell you how many wheels are powered:

- 4×2 – one powered axle

- 6×4 – two powered axles for better traction and load support

Tractors are made to pull different trailers depending on the job. From tankers to flatbeds, it all starts with the right tractor setup.

2. What is Semi-Trailer?

Back when I started, I assumed the trailer was just part of the truck. I didn’t know it had a name—or that it worked so differently from regular trailers.

A semi-trailer is the long cargo unit that attaches to the tractor. It doesn’t have a front axle. That means it can’t stand or move on its own. It needs a tractor to hold up the front and pull it.

This setup makes turning easier and helps carry heavy loads without needing extra wheels.

You’ve probably seen semi-trailers on the road every day. They’re used to haul almost everything:

- Pallets of goods

- Heavy machinery

- Refrigerated food

- Fuel and liquids

- Livestock

Features

A semi-trailer may look simple at first glance, but it’s built to do serious work. Here are the key features that make it function:

- No Front Axle: Unlike a regular trailer, a semi-trailer doesn’t have wheels at the front. It relies on the tractor to support that end.

- Landing Gear: These are the foldable metal legs near the front. You crank them down when the trailer is parked and not connected to a tractor.

- Rear Axles: Most semi-trailers have two or more axles at the back to carry the load. The number can vary depending on weight needs and legal limits.

- Connection Point (kingpin): This is the steel pin underneath the trailer that locks into the tractor’s fifth-wheel coupling. It’s what joins the two parts together.

- Cargo-Specific Builds: Some trailers are enclosed, some are open. Others are made to handle liquids, cold goods, or heavy loads.

Have you ever thought all trailers were the same? I did too—until I started seeing how each one is built for a different job.

3. Types of Tractor and Semi-Trailer

When I first started, I thought all tractors and trailers were the same. I quickly learned that choosing the right type makes a big difference in performance, fuel use, and safety.

Here’s a simple breakdown to help you understand what’s out there.

Types of Tractors

- Day Cab: No sleeper space. Great for short trips or local deliveries.

- Sleeper Cab: Comes with a sleeping area. Used for long-distance hauls and overnight trips.

- Heavy Haul Tractor: Built for extra-heavy loads. Has more axles and a reinforced frame.

- 4×2 Tractor: One powered axle. Good for lighter loads and city routes.

- 6×4 Tractor: Two powered axles. Offers better grip for heavy or rough road conditions.

Types of Semi-Trailers

- Dry Van: Enclosed trailer for boxed or palletized goods. Keeps cargo protected from weather.

- Flatbed: Open platform with no walls or roof. Used for steel, pipes, and oversized items.

- Reefer (Refrigerated Trailer): Temperature-controlled. Moves frozen or chilled products like food or medicine.

- Tanker: Sealed trailer for liquids or gases. Common in fuel, milk, or chemical transport.

- Lowboy: Sits low to the ground. Ideal for moving tall or heavy machinery.

- Livestock Trailer: Ventilated design for moving animals. Built for safety and easy cleaning.

Every setup has a purpose. Once you know what each type does, picking the right combo gets much easier.

4. Weight Limits Capacity

Back when I started, weight limits felt like numbers on a page. I didn’t fully get how the tractor and trailer split the load—or why it even mattered. That changed the day I overloaded a trailer and had to offload at the scale, in front of everyone. Not my best moment.

The truth is, tractors and semi-trailers carry weight differently, and each one has a limit. Learning how they work together can save you time, money, and frustration.

Gross Vehicle Weight Rating (GVWR)

The tractor has its own GVWR. This covers the cab, engine, driver, and any fuel or tools on board. Most fall between 33,000–52,000 lbs, depending on build.

The semi-trailer has a separate GVWR. This rating tells you how much cargo it can carry, including its own weight. Trailers often range from 34,000 to 80,000 lbs, depending on the axle setup and use case.

Add both together, and you get the total legal weight for your rig.

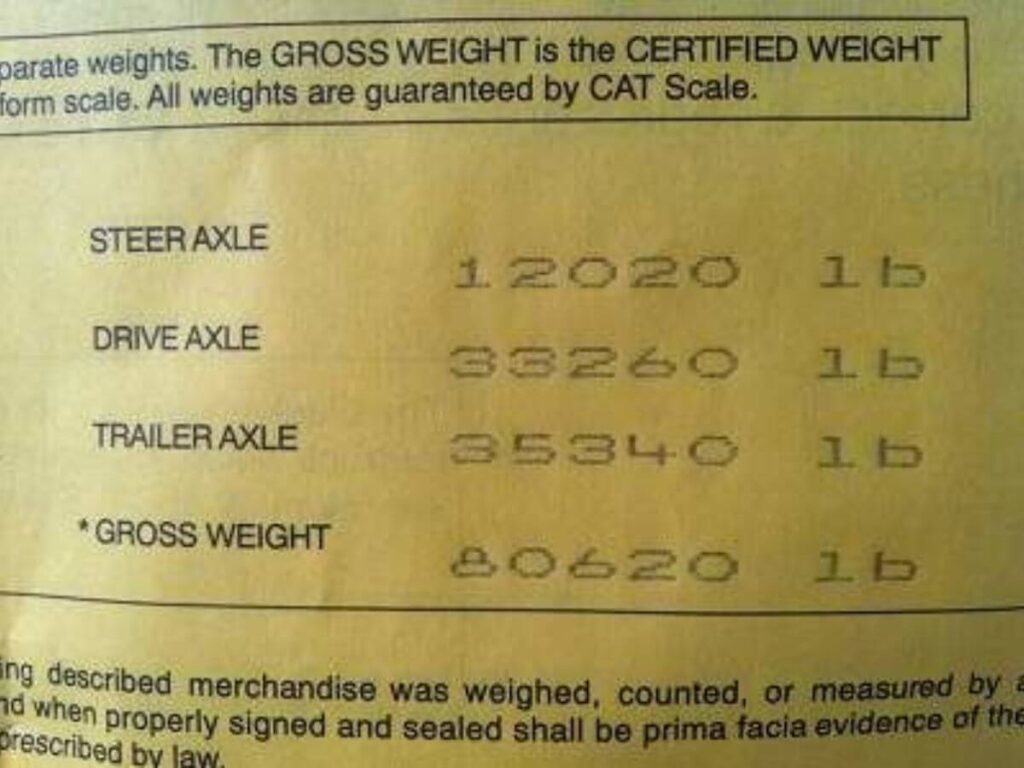

Axle Load Limits

Tractors and trailers both rely on axles to carry weight. Here’s how the load usually breaks down:

- Tractor (Steer Axle): 12,000 lbs

- Tractor (Drive Axles): 34,000 lbs

- Trailer (Tandem Axles): 34,000 lbs

The tractor pulls the load and carries the front-end weight.

The semi-trailer holds the cargo and supports the rest.

Tandem and Tridem Axle Configurations

- Tractors often use 6×4 setups (tandem drive axles) for better traction and stability.

- Semi-trailers may have tandem or tridem axles to support heavier cargo and spread weight more evenly. Tridem systems are common in Canada for longer hauls.

More axles = more weight capacity and less strain on roads.

Legal Weight Limits by Region

Every country has different rules:

- U.S.: Total limit for tractor + trailer = 80,000 lbs

- Canada: Up to 137,500 lbs with tridem setups

- Europe: Around 88,000 lbs (40,000 kg) for standard rigs

What’s legal for your trailer might not be legal for your tractor—especially across borders. Always check regional limits.

5. Cost Comparison

Honestly, at first I had no idea how much things really cost. I figured the trailer—being the bigger piece—must be the most expensive. But after talking to fleet owners, mechanics, and doing my own math, I found out that most of the money goes into the tractor, not the trailer.

And that matters—because whether you’re buying, leasing, or trying to set your budget, you need to know where your money’s going. It’s not just about the sticker price. It’s about how long each part lasts, how much it costs to run, and what kind of return you’ll actually get.

Tractor Costs and Value

Expect to pay $120,000 to $160,000 for a new tractor. You can find used ones for $40,000 to $90,000, but you’ll likely spend more on repairs down the road.

Why it costs more:

- It’s the power source

- Needs more maintenance

- Has the engine, transmission, and electrical systems

- Comes with emissions controls, sensors, and safety tech

ROI Tip: If you drive full-time, the tractor pays off over time. It’s your money-maker. A well-maintained tractor can last 5–10 years, sometimes more. But keep in mind—it’s also where most breakdowns happen.

Semi-Trailer Costs and Value

A new dry van trailer runs around $35,000 to $50,000. Reefers, tankers, and specialty builds can reach $70,000 to $100,000. Used trailers usually range from $15,000 to $35,000 depending on age and condition.

Why it costs less:

- No engine or fuel systems

- Lower maintenance

- Fewer moving parts

ROI Tip: A trailer can last 10–15 years or more if you take care of it. That makes it a better long-term investment in many cases—especially if you rotate tractors but keep the same trailer fleet.

The tractor costs more upfront and over time. But it’s also where your revenue starts—it moves the freight, it builds the miles, and it pays the bills.

The trailer costs less to buy and maintain, but without it, you’re not hauling anything.

6. Maintenance Responsibility

If you’ve ever shared equipment between drivers or companies, you know how fast confusion can happen. Who’s fixing what? Who’s paying for it?

When it comes to maintenance, the tractor and the semi-trailer each come with their own list of tasks—and responsibilities often depend on ownership and usage agreements.

Tractor Maintenance

The tractor does the heavy lifting, and it’s where most moving parts live. That means more things can go wrong—and faster.

If you own the tractor, you’re usually responsible for:

- Repair Engine: This includes oil leaks, faulty sensors, or worn parts. A bad engine keeps the whole rig parked.

- Change Oil and Filters: Regular oil and fuel filter changes keep the engine running clean. Skipping this can shorten engine life.

- Service Brakes: Worn pads or air leaks need quick attention. Brake failure puts you and others at risk.

- Fix Transmission or Drivetrain: These systems move power from the engine to the wheels. Any issue here affects hauling and control.

- Check and Replace Tires: Tires wear down fast with heavy loads. Blowouts are costly and dangerous.

- Inspect Electrical Systems: This covers lights, sensors, and wiring. Electrical faults can kill signals or cause false warnings.

- Emissions and Safety Checks: Modern tractors use DEF and other systems to meet emissions rules. These need regular service.

Trailer Maintenance

Trailers are simpler, but they can’t be ignored. Ignoring small issues often leads to bigger ones on the road.

Here’s what trailer maintenance usually includes:

- Check Brake Systems: Trailers have their own brakes. Air leaks or worn pads can cause poor stopping power.

- Rotate and Replace Tires: Trailer tires wear unevenly if not rotated. Replacing them early helps avoid costly roadside calls.

- Repair Suspension Systems: A damaged suspension leads to rough rides and cargo damage.

- Inspect Landing Gear: These support the trailer when unhooked. Bent or stuck gear makes pickups difficult.

- Fix Lighting and Wiring: Tail lights, brake lights, and turn signals are all legal requirements. No lights = big fines.

- Maintain Doors, Seals, and Floors: Doors must latch securely. Seals keep out water. Weak floors risk collapse under heavy loads.

I once opened a trailer door to find rainwater had soaked half the load—just because a rubber seal wasn’t replaced in time.

7. Common Applications by Industry

Different jobs need different trailer setups. What works for retail won’t cut it on a mining site. Over the years, I’ve seen how important it is to match the right equipment with the right work.

Here’s how tractors and semi-trailers are used in key industries:

Construction & Mining

In construction and mining, tractors are often paired with dump trailers or lowboys. These setups are built for rugged terrain, moving bulk materials like gravel, sand, or machinery. Off-road durability and high torque are essential, especially when navigating unpaved sites or hauling oversized loads. These industries demand strength over speed.

Logistics & Transportation

For logistics and freight transport, tractors usually pull dry vans or refrigerated trailers. These are the workhorses of regional and long-haul shipping. Fuel economy, weight efficiency, and route flexibility are key, especially when moving between warehouses, hubs, and cities. These setups are built for uptime and reliability.

Agriculture & Food

In the agri-food sector, tractors often haul insulated trailers or livestock carriers. Produce and meat must stay fresh, so temperature control, ventilation, and hygiene standards are non-negotiable. Access is also important—trailers need to be easy to load and clean. Whether it’s grain or cattle, the focus is on preserving quality during transport.

Oil, Gas & Energy

In this sector, tractors typically pull tankers for fuel or heavy-equipment trailers for site operations. These hauls often involve hazardous or high-value cargo. That’s why ADR-compliant vehicles, strong braking systems, and reinforced frames are required. Safety and stability come first—one mistake can shut down an entire job.

8. How To Choose The Right One For Your Needs

Choosing between different tractors and trailers can feel like a big decision—but it doesn’t have to be. I’ve made the mistake of chasing specs instead of thinking about the actual job. The truth is, the right setup depends on what you haul, how far you go, and what kind of work you’re doing.

Let’s break it down.

Know Your Distance and Route Type

Short hauls don’t need fancy setups. A day cab works fine and is cheaper. Long routes? Go with a sleeper cab so drivers can rest legally and safely. If you’re on the highway, fuel economy matters. If you’re off-road or on job sites, durability matters more.

Consider Your Roads and Terrain

Are you on paved roads all day—or are you going into job sites, gravel roads, or farms? Rough terrain needs higher torque, stronger suspension, and good ground clearance. Don’t overlook this—trailers not built for rough roads break faster.

Match Your Maintenance Plan

New equipment costs more upfront, but it’s easier to maintain early on. Used tractors or trailers save money—but they often need more upkeep. If you have a good maintenance team or contract, you can handle older gear. If not, newer may be smarter long-term.

Think Long-Term, Not Just Today

The best setup isn’t always the cheapest or the newest—it’s the one that makes your job easier every day. Look at what you’ve hauled over the past year. Think about what’s changing in your business. The right gear today should still work for you two or three years from now.

Conclusion

I still remember staring at that trailer, unsure where the engine even was. Now, I know the difference—and so do you.

This guide walked you through tractors, trailers, weight, cost, and how to choose the right combo. You’ve got the knowledge. Now it’s time to make the move.

Ready to stop guessing and start owning the right setup?

Contact us today to get expert help that fits your work and your roads. We’re here to help you move forward—with clarity, not confusion.